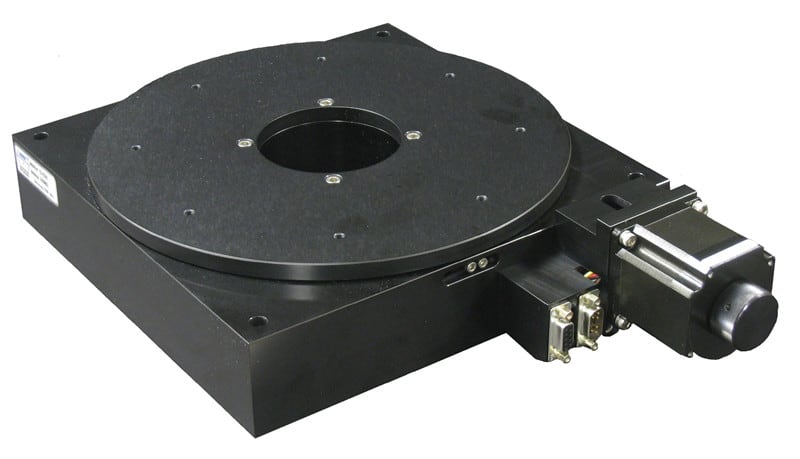

The Dover RTR™ series motorized rotary stage incorporates stiff crossed roller bearings and a precision worm gear drive, and is used for many factory automation applications as well as OEM medical equipment for rotating sample queue columns.

Search by Category

Specifications

| wdt_ID | Base Model | RTR - 4 | RTR - 6 | RTR - 8 | RTR - 10 | RTR - 12 |

|---|---|---|---|---|---|---|

| 1 | Travel Diameter(mm) | 100 | 150 | 200 | 250 | 300 |

| 2 | Table Diameter (inches) | 4 | 6 | 8 | 10 | 12 |

| 3 | Travel (degrees) | 360 | 360 | 360 | 360 | 360 |

| 4 | Positional Accuracy (degree) | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| 5 | Bi-directional Repeatability (± μm)1 | 0.01 | 0.007 | 0.007 | 0.005 | 0.005 |

| 6 | Load Capacity (kg) | 15 | 30 | 30 | 45 | 45 |

| 7 | Maximum Velocity (RPM) | 20 (45:1 Gear) | 25 (36:1 Gear) | 25 (36:1 Gear) | 5 (180:1 Gear) | 5 (180:1 Gear) |

| 8 | Total Mass (kg) | 2.3 | 4.1 | 6.4 | 9.1 | 12.7 |

Description

The Dover RTR™ series stages are available in 4-, 6-, 8-, 10-, and 12-inch diameter rotary stage versions that include a preloaded, anti-backlash drive assembly to provide exceptional angular accuracy and repeatability. There is a standard internally mounted Hall effect reference sensor that is wired directly to a screw locking connector for homing position registration accurate to a single step. A stepper motor with a manual knob and a flexible coupling are included with this motorized rotary stage. A second sensor can also be installed to electrically restrict rotary table travel in applications where the full rotational travel needs to be limited to a specific angle of travel less than 360 degrees.

Clear apertures (or through hole) are optionally available in different diameters. Our integral rotary motor encoder can be specified with our RTR™ series rotary stage, where it provides 0.001-degree resolution encoder feedback when combined with a 180:1 worm gear ratio, 200 step-per-revolution stepper motor, and a divide-by-ten micro-step drive. For increased rotary motion resolution, 400-count stepper motor or rotary servo motor are available.

Applications

The most popular Dover rotary stage used for many factory automation applications as well as OEM medical equipment for rotating sample queue columns.

Downloads

Datasheets