Solving the World's most challenging motion problems

Dover Motion offers everything an OEM needs to design, build, and test new motion systems from prototypes to production.

- 60+ years designing and manufacturing solutions for leaders in Life Science & Diagnostics

- ISO 9001: 2015 Total Quality Management certification

- Products assembled in the USA

Put the strength of a Fortune 500 company to work for you

As a Fortive company (NYSE:FTV), Dover Motion has the stability and resources of a multi billion dollar organization.

Global Manufacturing and Sourcing Capabiltiies

Ralliant Business System (RBS) is part of our organizational DNA. Adapted from the famed Toyota Production System, RBS is a framework focused on continuous improvement, customer-centric processes, visual management and Lean manufacturing. All Dover Motion employees are trained in the tools of RBS which are designed to eliminate waste, minimize risk, ensure on-time delivery, promote safety and, provide a superior experience to our customers. Dover Motion is a provider of product realization services with a focus in healthcare markets. Dover Motion, located outside of Boston, MA is vertically integrated for the design, manufacturing and test of motion control products and subsystems. The Global footprint provided by Ralliant results in efficient low cost region sourcing and 24/7 worldwide coverage. Contact Dover Motion to leverage our global footprint.

Focus on your technology, trust us with the motion

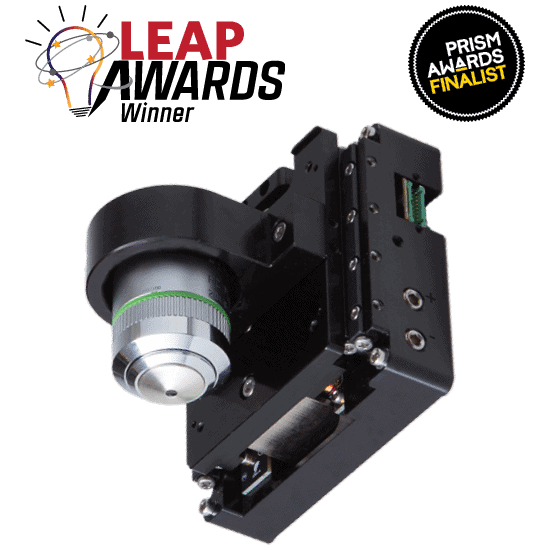

Dover Motion has more than 60 years of experience designing and manufacturing standard linear and rotary stages as well as customized stages and high level motion assemblies. Recent Dover Motion patented innovations have been receiving industry awards and disrupting the motion control market. We have created a novel stage architecture by embedding high performance precision electronics required to control motion within the stage without increasing its size. The result is the only direct drive linear stage of its kind and allows bulky external cabling and control boxes to be eliminated. Contact Dover Motion to use our expertise for your advantage.

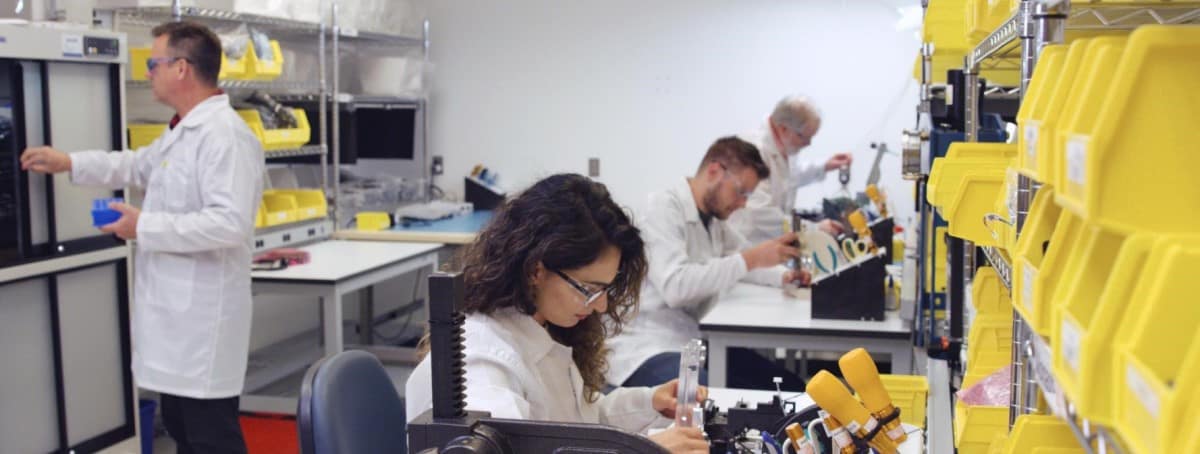

Manufacturing

Our innovative motion control product design and development is complemented by our in-house manufacturing capabilities, providing our clients with complete high level assemblies and full instrument manufacturing options for a single point of accountability. Our manufacturing mindset begins very early in the product development process by including manufacturing engineers on every project team to ensure a high quality and cost-efficient design and smooth well documented transfer to the build and test teams. Built on the foundation of ISO 9001 and using world recognized Ralliant Business System (FBS) tools, our manufacturing team provides flexibility, expertise, on time delivery, and quality products. We are able to scale up quickly due leveraging our vertically integrated factory and global supply chain to support small batch prototyping, medium volume pilot production and high volume production. Contact Dover Motion to benefit from our lean manufacturing approach.

Partnering for results

It is our goal to take care of the design and manufacturing of your motion system or high level assembly so you can focus on your unique technology. We’ve won multiple generations of instrument motion design projects with market leading Life Science and Diagnostic OEMs due to this approach. Our custom design engagements are managed by a dedicated project manager who leverages Ralliant Business System (RBS) tools for visual and daily management to provide “at a glance” knowledge of key metrics to continuously improve our On Time Delivery (OTD), Internal Quality DPM, and External Quality DPM.

- Reusing modules where appropriate to minimize risks and drive faster time to market

- Balancing onsite machining and offshore sourcing for fast prototyping and low-cost production

- Leveraging agile supply chain to continuously drive faster lead times

- Collaborating with clients to create innovative motion solutions

- Applying 60 years of experience to your specific industry and application

- Designing and manufacturing motion systems that fit seamlessly into your instrument