Kevin McCarthy, Chief Technology Officer

With over forty years of experience on thousands of positioning systems, Kevin possesses an unparalleled knowledge of all aspects of precision motion. With his physics and optics background, and years of experience designing custom solutions in cutting edge fields, Kevin brings exceptional context sensitivity to understanding customer's underlying needs.

Kevin's expertise goes far beyond his precision motion core. Kevin is as comfortable discussing the latest developments in camera and optics technologies, DNA sequencing, and fluorescence microscopy as he is discussing astronomy, AFMs, semiconduction inspection, fiber optic positioning, satellites, or any number of additional precision motion use cases.

Kevin is constantly thinking about how to improve products and how to push the envelope with what technology can achieve.

Kevin received a BS in Physics from MIT, and for many years ran one of the two private companies that now form Dover Motion.

Key Accomplishments

1982: Pushing the Envelope with Single Axis Positioning Systems

Kevin was constantly thinking about how to push the envelope with what technology could achieve. That determination lead him to design the NEAT 200 and 301 series. That stepper controller was based on a third party motion control board, but its ease of use was not good. Kevin used his experience from using and selling the NEAT-301 to design the NEAT 310M, a programmable microstepping drive and control, which had a 25 year run with thousands of units sold, with 'ease of use' being its central feature.

1986: Single Axis Leads to Multi Axis Positioning Systems

The success of the single axis comtroller led Kevin to develop a multi axis product, the DPS 2000, a four axis motion controller (all stepper), which was way ahead of its time. It had a 3 1/2 inch floppy disk drive in its front panel, which Steve Jobs had just introduced on the Mac. The 3 ½ floppy, a simple menu based keypad, and assembly code combined to enable automated motion. But the resolutions were utterly different than they are today. Back then, the typical stage resolution was 0.001", ~ 25 microns. This started an arms race in which customer requirements were always a little more precise than what existing technology allowed, which drove technological innovation in position resolution.

1995: Positioning System in NASA and ESA's SOHO Satellite

Kevin developed a positioning system that was installed on the SOHO (Solar and Heliospheric Observatory) satellite, a joint NASA-ESA mission that is located at L1, 1.5 million kilometers sunward from Earth. That is nearly four times as far as the Moon, and over 5,000 times the typical altitude of low earth orbiting satellites. Despite having been originally planned as a two year mission, SOHO is still going strong and is funded through at least 2025.

2003: Motion Innovations that Save Lives

Kevin worked with a start up digital pathology OEM to incorporate Dover Motion's noncontact, direct drive, linear motor technology for XY slide positioning, and also for Z objective focusing, using a novel flexure-based direct-drive stage in place of piezo actuators into their breakthrough instrument. The company achieved FDA approval in 2005, The instrument has dominated cervical carcinoma screening for over fifteen years.

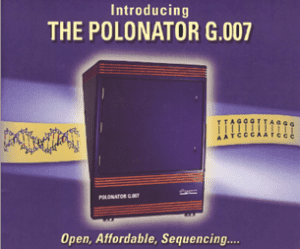

2008: The Pollinator DNA Sequencer

Kevin, along with world-renowned Harvard geneticist, Dr. George Church and his colleague Rich Terry, collaborated on a second generation DNA sequencer utilizing the leading detection technique, fluorescence microscopy. The result of this effort was the "Polonator", named for Dr. Church's emulsion polymerase colony, dubbed "polonies", clonal amplification technique. While ultimately the Polonator's chemistry had read length limitations, which capped the total number of units sold, it was anything but a failure. Subsequent iterations were supplied to another Boston area DNA sequencing start-up, as well as being repurposed for a successful spatial sequencing company cofounded by Dr. George Church and Rich Terry.

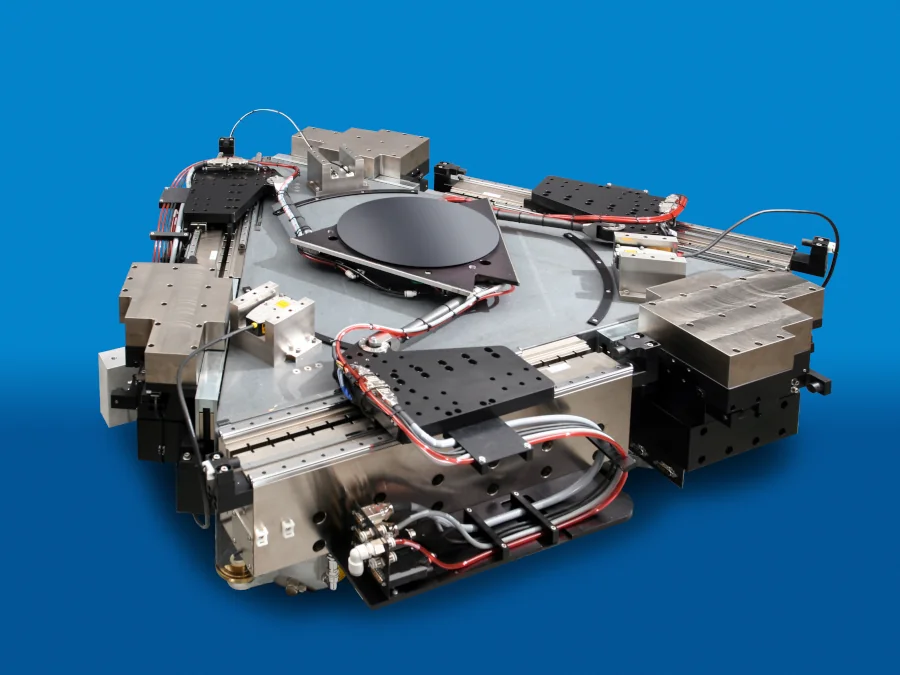

2010: The Dover Motion Delta Stage

Kevin led a team that partnered with Active Precision to develop the Dover Motion Delta Stage. This was an unconventional, very high performance planar air bearing X-Y stage that used laser interferometer feedback, and had a uniquely high figure of merit Ks, which relates acceleration to waste heat. Conventional planar air bearing stages use an “H” configuration, with a high mass moving-magnet bridge structure that limits acceleration. In the Delta Stage, all motor magnet structures are stationary, and only the lightweighted air bearing chuck-puck and its coils move, driven by three parallel silicon carbide link arms. The Delta Stage is ~50X more power efficient than “H” gantries of comparable travel, dissipating less than 15 watts per coil during continuous 3G acceleration. Counterforce actuators eliminated both inertial forces and center of gravity shift throughout travel. A paper on the Delta stage was presented at MIT for an ASPE conference in 2010; that paper is available here.

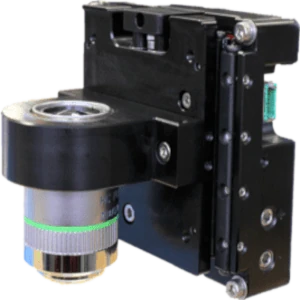

2018: Award-Winning DOF-5 Objective Focusing Stage

Dover Motion was approached by an OEM customer that wanted a new high performance and low cost Z objective focusing stage. Standard approaches were out of their budget. Dover Motion needed a revolutionary innovation to get the price down dramatically. This challenge inspired Kevin to put the controller directly inside the stage, eliminating the need for extra parts and cabling while saving space in the instrument. It would be compact, high performance, and cost effective.

The resulting design was the DOF-5, or the Dover Objective Focuser, 5 mm travel, which is also the acronym for depth of field. In 2019, the DOF-5 won the LEAP Award, and was named a finalist in the 2019 SPIE PRISM Awards for Optics & Optomechanics. The DOF-5 design is covered under U.S. Patent 10,367,436, which lists Kevin as the inventor.

2020: Atomic Level Positioning

Kevin led the development team of Dover Motion's linear encoder which has a resolution that can be set as low as 305 picometers. That's less than 1/3 of a nanometer, which is pretty much identical to the Van der Waals diameter of a single aluminum atom. Literally Atomic Level Positioning!

2020: Pushing the Boundaries with SmartStage™ XY

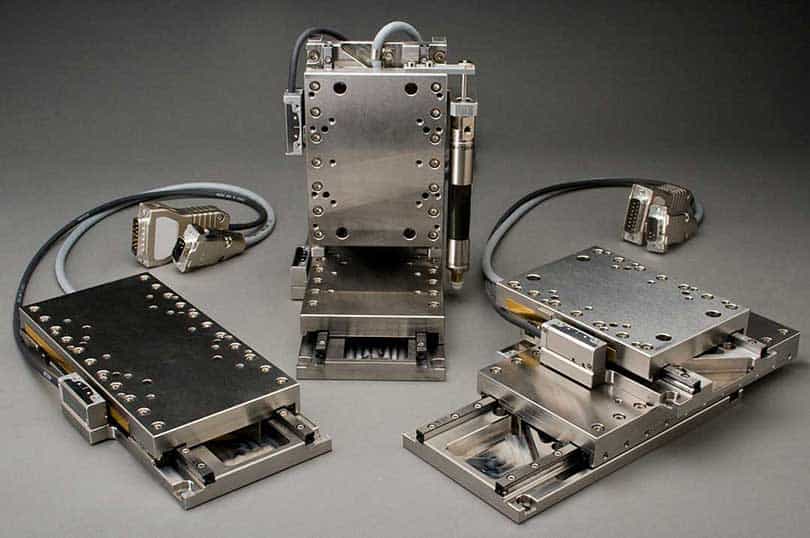

Given the success of the DOF-5, it was natural to start pushing the boundaries of the current capabilities of Dover Motion's traditional travel XY stages, which had been a goal of Kevin's since the year 2000, but it was only recently that the chips and other resources needed to make it a reality fell into place. Kevin felt confident that the Dover Motion team could put a complete low noise drive, high performance servo motion controller in the same cross-section as the existing line of MMX stages. The goals for this innovation were aggressive, targeting the 50 mm stroke MMX stage footprint, which is 110 mm long and only 25 mm tall. That was going to be difficult, as a lot of parts needed to fit into a very small space including the crossed roller guideways, a linear motor with a magnet array and coil, 1.25 or 5nm resolution encoder, limit switches, and all the electronics to support the communications and I/O. Determining how to put a complete 20 kHz high performance servo drive and control in the same footprint was also going to be a challenge.

The Dover Motion team led by David Thomas rose to the occasion, and under Kevin's leadership, managed to fit everything into the compact 50 mm travel form factor, which was trademarked as SmartStage™ XY. In 2021, the SmartStage™ XY was awarded both the LEAP and IDEA! awards for innovation in motion control. The controller and the stage are incredibly compact, so this is highly differentiated, and patent protected. Kevin is listed as the inventor on both of these US patents 10,374,530 and 10,367,436.

In The News

Kevin McCarthy Celebrates 40 Year Anniversary with Dover Motion

June 28, 2022

April marked a very special milestone for Dover Motion. Kevin McCarthy, Chief Technology Officer, celebrated his 40-year anniversary. Read this article to learn more about Kevin's very interesting path to CTO at Dover Motion, as well as celebrate his amazing accomplishments along the way.

Read the full article here.

"Automation in Microscopy Captures the Whole Sample" Webinar

January 25, 2021

In January 2021, the Photonics Spectra Conference featured over 70 presentations in four technology tracks - lasers, optics, spectroscopy, and biomedical imaging. Click here to view Dover Motion's CTO, Kevin McCarthy's, presentation titled "Automation in Microscopy Captures the Whole Sample".

Read the full article here.

View the webinar here.

Automated Imaging Classroom

Dover Motion CTO, Kevin McCarthy dives into motion control concepts and calculations for imaging applications.