Motion Solutions

Dover Motion’s core strength is collaborating with our clients to understand their projects and configure the right motion solution to fit their unique applications. With more than 60 years of experience, we understand your needs and can provide you with the flexibility needed to hit even the most challenging cost and schedule targets.

- Reusing modules where appropriate to minimize risks and drive faster time to market

- Balancing onsite machining and offshore sourcing for fast prototyping and low-cost production

- Leveraging agile supply chain to continuously drive faster lead times

- Collaborating with clients to create innovative motion solutions

- Applying 60 years of experience to your specific industry and application

- Designing and manufacturing motion systems that fit seamlessly into your instrument

Our Motion Solutions Expertise

We have more than six decades of experience creating motion solutions for the life sciences, diagnostics, and factory automation industries, designing multi-axis stages for applications such as imaging, optics, focusing, positioning, and motion control. We specialize in overcoming all sorts of motion challenges, from controlling motion at the nanometer level to driving high frame rates and critical focus in automated imaging systems. Many of our products have been in the field for decades, running reliably in incredibly challenging conditions such as the crowded confines of a diagnostics instrument or the high-vacuum setting of outer space.

On-Time Delivery at the Lowest Possible Cost

Dover Motion is a proud Ralliant company (NYSE: RAL), and we operate with deep roots in the Ralliant Business System (RBS). RBS is a proven framework focused on continuous improvement, customer-centric processes, visual management, and lean manufacturing.

All employees are trained in the powerful tools of RBS, which are designed to eliminate waste, minimize risk, ensure on-time delivery, promote safety, and provide our clients with a superior experience. RBS, coupled with the global purchasing power and reach that come with being part of Ralliant, allows us to provide our clients with customized motion solutions that meet any cost or timeline goal.

The Right Linear Positioning System for Your Application

With over 60 years of experience in life sciences, diagnostics, and factory automation, we understand your industry's challenges and offer the flexibility to meet your cost and schedule goals. Whether you need a standard motion product or a completely custom linear positioning system, we’ll work closely with your team to ensure your project meets even the toughest design and budget targets. Our collaborative approach ensures we provide motion solutions that align perfectly with your requirements.

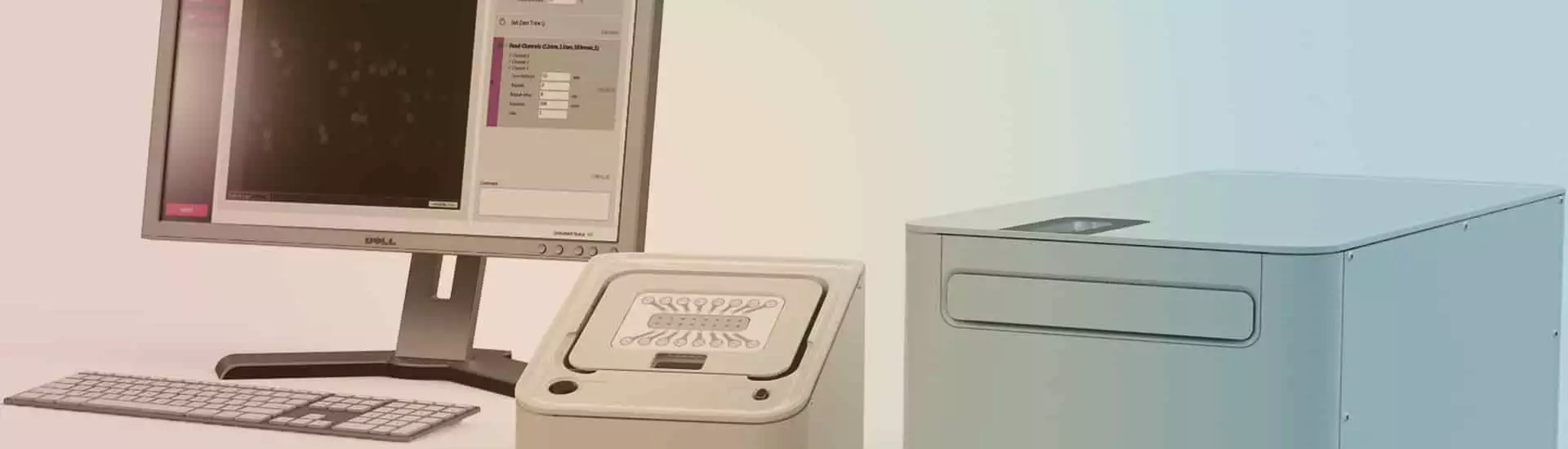

Through concurrent and collaborative engineering, Dover Motion developed a compact custom XYZ stage motion solution to produce high-precision cell imaging in parallel with the instrument design.

Dover Motion worked with Invetech to define the motion system requirements and tightly integrate the hardware in the overall instrument design, enabling the client to get the funding they needed to continue their project.

To minimize the overall size, Dover Motion used compact stepper motors with integrated lead screws. Placing the motors within the stage structure enabled all wiring to be concealed and to exit at the bottom of the stage.

Examples of Success

Through concurrent and collaborative engineering, Dover Motion developed a compact custom XYZ stage motion solution to produce high-precision cell imaging in parallel with the instrument design.

- A client was developing a digital cytology instrument for cancer screening

- Their prototypes, based on proprietary ultrasonic standing wave piezoelectric motors, had been unable to focus at the resolution required and were pushing the client beyond their cost and timeline targets

- We collaborated to create an XY stage and a Z stage that met performance requirements at one third the cost and got the client back on track with their timeline and budget

- The instrument received FDA approval and captured >70% of the target diagnostic test market with throughput 3x the previous benchmark

Dover Motion worked closely with Invetech to define the motion system requirements and tightly integrate the hardware in the overall instrument design.

- MyCartis needed a motion control system to move and focus a microscope that would image thousands of 40-micrometer fluorescing microspheres arrayed on a plate.

- The motion solution had to fit into the confined space of this benchtop instrument in a point of care setting.

- The positioning system needed to be developed in parallel with the instrument in order to hit a 12-month timeline.

To minimize the overall size, Dover Motion used compact stepper motors with integrated lead screws. Placing the motors within the stage structure enabled all wiring to be concealed and to exit at the bottom of the stage.

- A company was developing a new 3D optical metrology system but no off the shelf solutions provided the user friendly packaging they desired.

- The Dover Motion team worked closely with the customer to understand their project and create a new design that met their goals and was also aesthetically pleasing and safe for end users.

- We created a new kind of XY stage that placed the motors, all the wiring, and control boards within the stage for a small footprint and sleek appearance.

- This new kind of monolithic XY stage for 3D metrology was so successful that it has become a Dover standard motion solutions product.