Trusted for the Most Demanding Automated Microscopy Instruments

Dover Motion offers everything an OEM needs to design, build, and test new precision motion systems from prototypes to production.

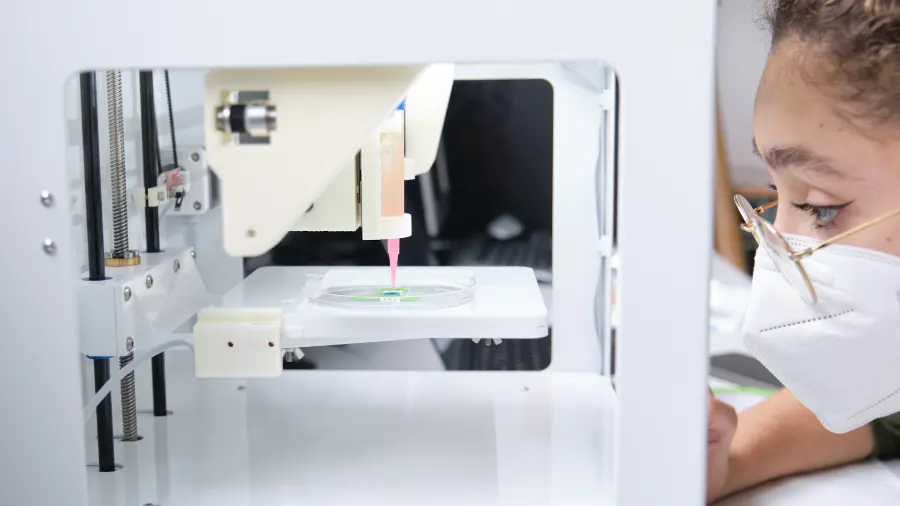

Engineering Precision Motion for the Most Demanding Applications

From concept to full-scale production, we engineer and deliver advanced motion systems, partnering with OEMs for critical applications.

Our Latest Innovative Precision Motion Stages

Our Latest Innovative Precision Motion Stages

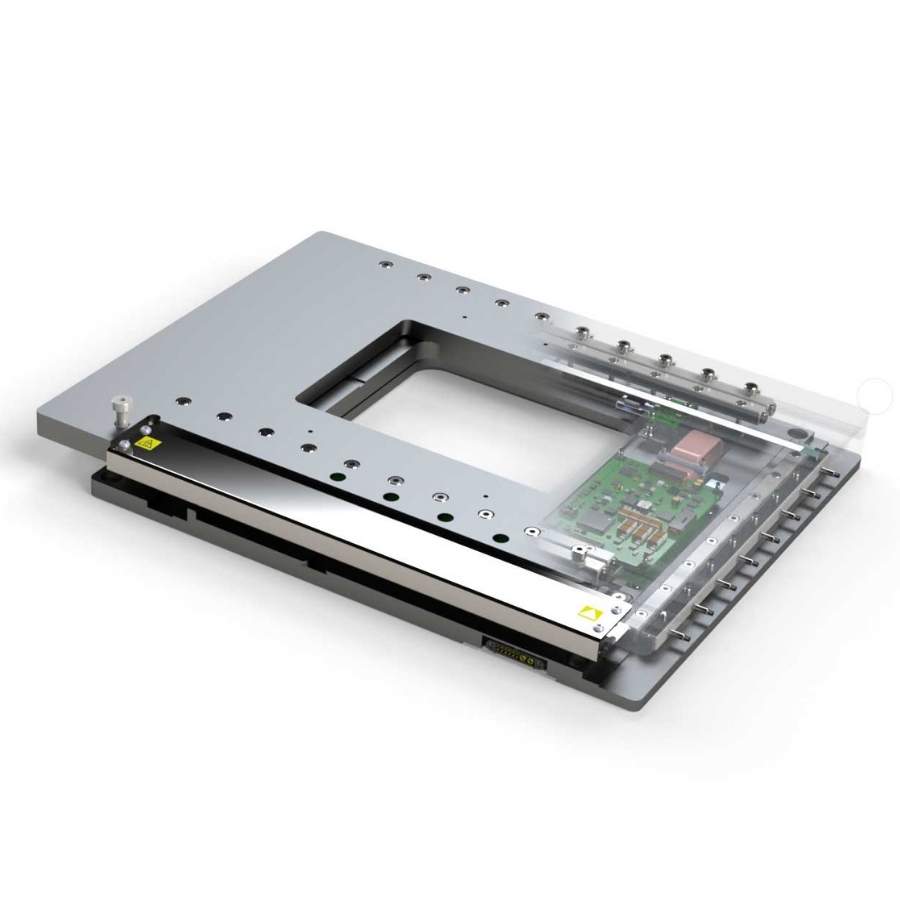

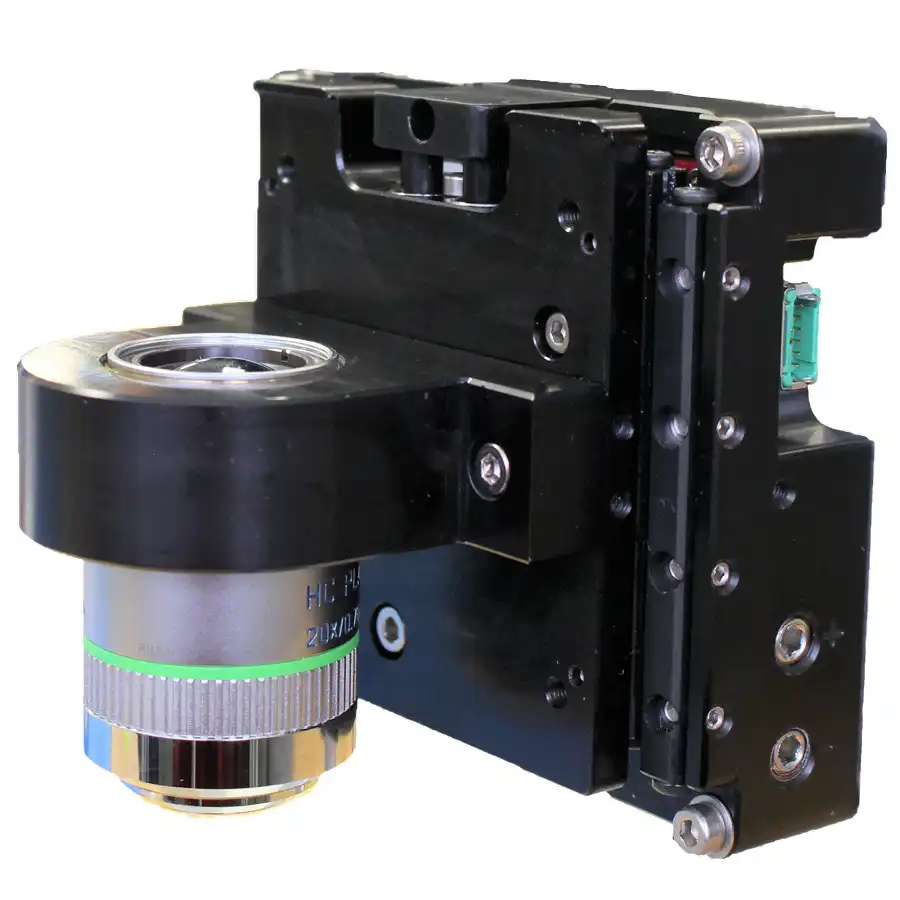

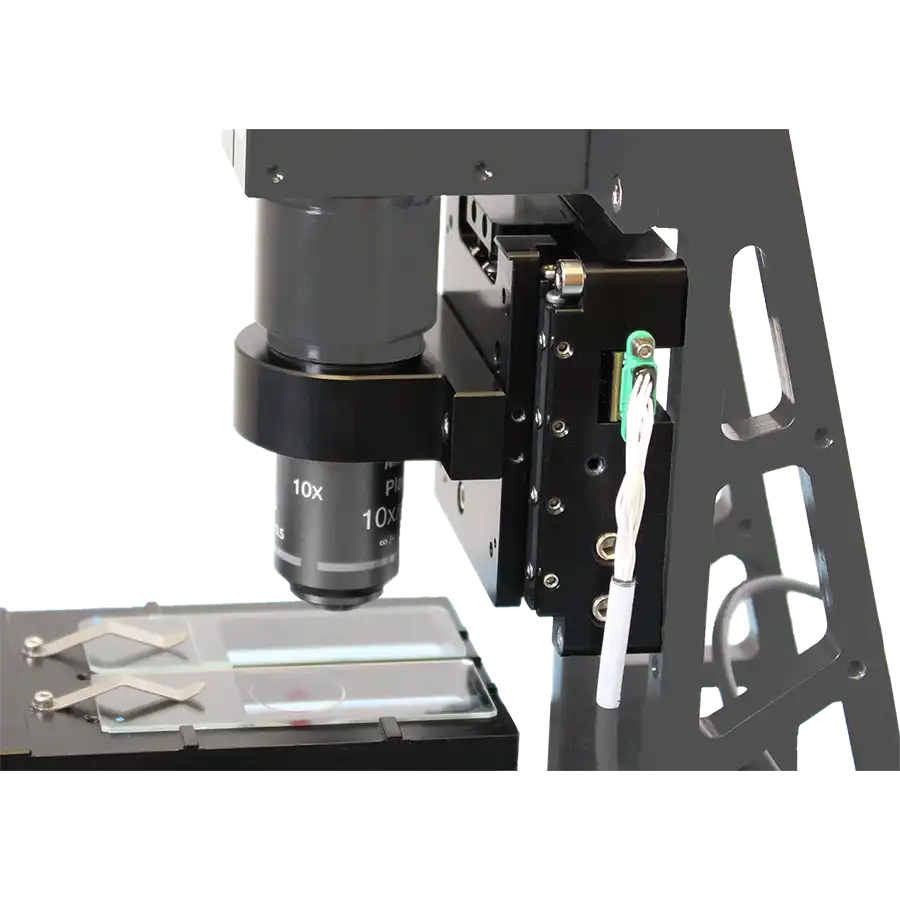

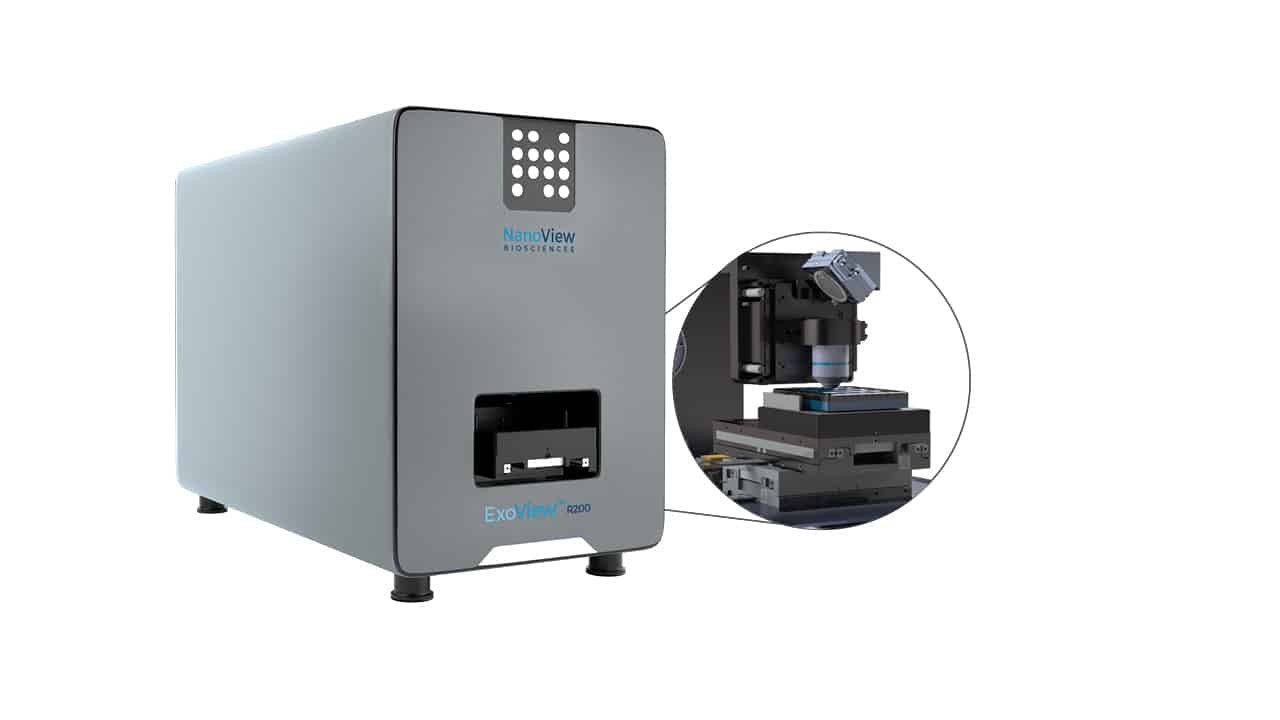

Improving Biomarker Imaging with SmartStage™ XY & Z

Find out how Dover Motion’s combined solution for X, Y, and Z precision linear stages allowed NanoView Biosciences to improve the throughput and reliability of their next-generation instrument.

”The SmartStage XY and Z improved the design and manufacturability of our instrument by eliminating external cables and controllers. The design and quality of these stages improved the overall robustness and performance of our instrument.“ -David Freedman, President and COO, NanoView Biosciences

Over 22,000 Motion Systems Shipped to Fortune 500 Companies

Join the Dover Motion team

Our most valuable asset is our people. Our employees influence every aspect of our business—from leading teams and finding solutions to critical problems, to continuously improving our processes.