Vertical Z Stages

A Z stage is a unique type of linear translation stage which provide high precision linear motion in the vertical direction. Z stages are typically used for objective focusing in biomedical, life science and diagnostic instruments utilizing automated microscopy. DNA sequencers, cell imaging instruments, and digital pathology scanners are just a few of the many applications for digital microscopy solutions. Dover Motion offers a variety of standard vertical Z stage options in addition to our core strength in collaborating with our clients to understand their needs and configure optimized vertical Z stage solutions to fit their unique application.

Z Stage Products

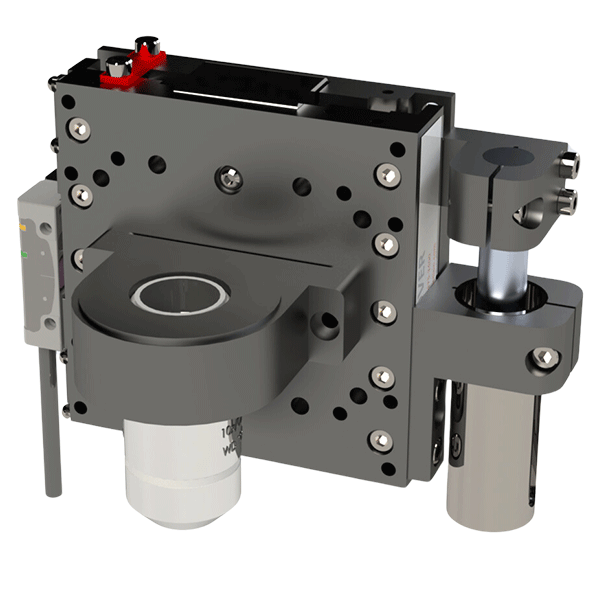

The DOF series vertical Z stage has been optimized for optical microscopy applications. Eliminates alignment headaches.

| wdt_ID | Travel | 5 mm |

|---|---|---|

| 1 | Resolution | 1.25 nm |

| 2 | Repeatability | < 50 nm |

| 3 | Bandwidth | > 225 Hz |

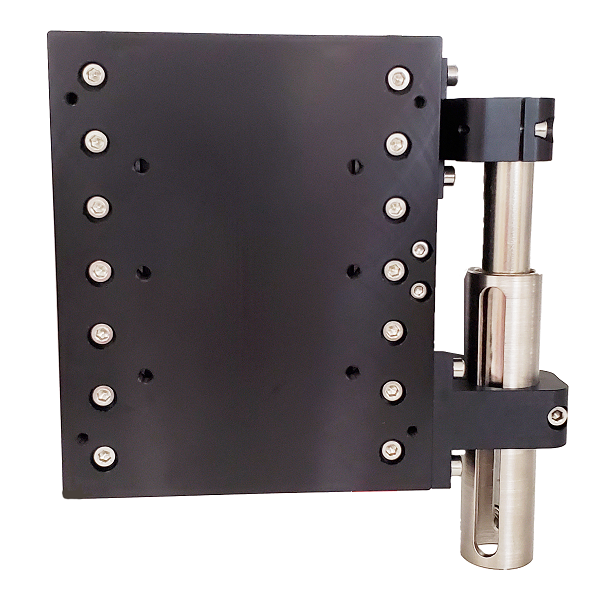

The MMX-Z-25 is our compact linear stage, offering exceptional stiffness and servo bandwidth, ideal for high-throughput imaging applications.

| wdt_ID | Travel | 25 mm |

|---|---|---|

| 1 | Accuracy | 6 μm TIR |

| 2 | Repeatability | ± 0.4 μm |

| 3 | Payload w/magnetic CB | 1.5 kg |

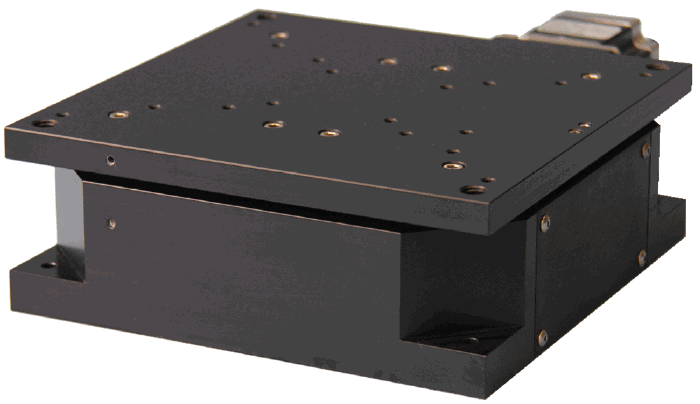

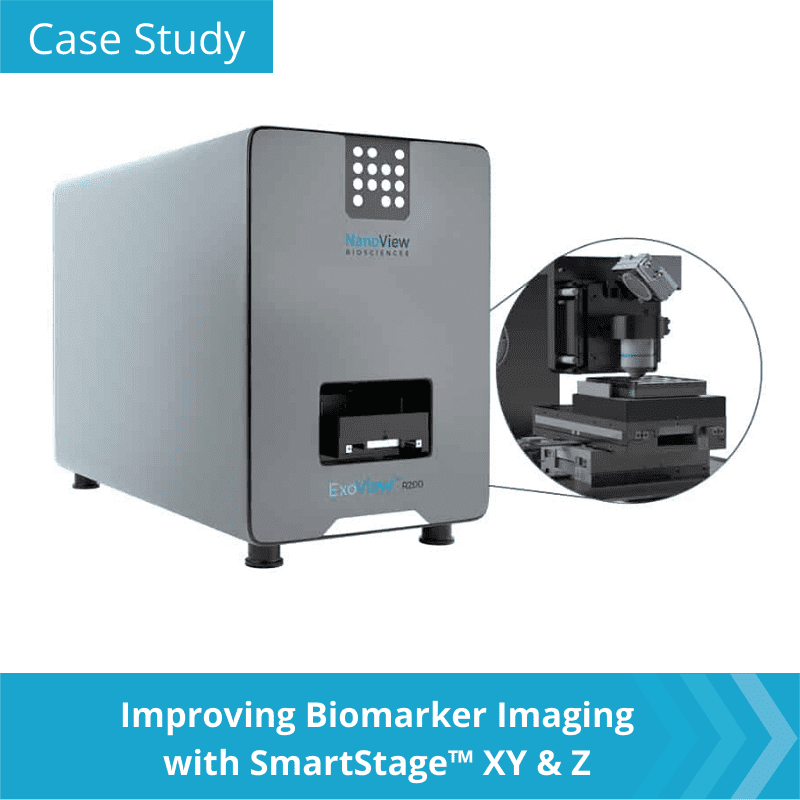

The SmartStage™ Z-50 provides a unique combination of travel distance and precision for vertical Z axis stage applications.

| wdt_ID | Travel | 50 mm |

|---|---|---|

| 1 | Resolution | 5 nm |

| 2 | Accuracy | 10 μm |

| 3 | Repeatability | .8 μm |

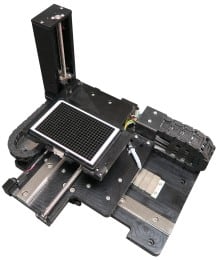

Our elevator wedge vertical ZE stage provides a small footprint with a 200-millimeter-square moving table.

| wdt_ID | Travel | 12 - 38 mm |

|---|---|---|

| 1 | Accuracy | 15 μm TIR |

| 2 | Repeatability | < ± 1.5 μm |

| 3 | Payload | 10 kg |

Custom Designs

We have over 50 years of experience working with OEMs to optimize motion for objective focusing and vertical Z lifting applications.

Our engineers have developed unique motion control architectures for precision motion specifically tailored for vertical Z motion within many applications.

When it is time to develop your next focusing instrument, consult with our motion industry experts to determine which of the latest technologies make the most sense for your application.

Additional Resources

Z Stages FAQ

A Z stage, also referred to as a Z-axis stage, is a precision positioning device designed to provide controlled vertical movement. Often integrated with XY stages to create multi-axis positioning systems, Z stages enable precise and repeatable positioning in three dimensions. This enables vertical and horizontal movement, providing complete control over positioning.

These devices come in various configurations to suit different needs and applications. These devices are particularly valuable in microscopy, life sciences, and metrology, where accurate vertical positioning is essential.

The primary function of a Z stage is to provide accurate and repeatable vertical motion. This is crucial in applications requiring precise positioning, such as microscopy and inspection. Imagine examining a tiny object under a microscope; the Z stage allows you to focus precisely at different depths without disturbing the sample. Z stages must overcome gravity's challenges to ensure stability and accuracy in vertical motion. They achieve this through robust design and high-quality components, such as precision linear guides and drives. These components minimize unwanted movement and vibrations, ensuring smooth and precise motion.

Z stages have bearings to constrain the motion along just the vertical axis. In order to overcome the forces of gravity a magnetic counterbalance or pneumatic counterbalance can be used to minimize the load on the Z stage motor. Another approach is to drive the vertical motion by moving a wedge horizontally, these are known as wedge Z stages.

While piezo actuators offer high precision for Z-axis (vertical) motion control, they have several limitations that make them less than ideal for some applications. Here's a breakdown of these drawbacks:

-

Limited travel range: Piezo actuators typically have a maximum travel range of around 300 nanometers, which can be insufficient for applications requiring larger movements, such as avoiding collisions with samples or finding the optimal focus plane for uneven samples.

-

Lower bandwidth: The stiffness of a piezo stage translates to lower bandwidth compared to stages using linear motors or screws. This can make them unsuitable for applications demanding high-speed motion control or those prone to vibrations from external sources like pumps or fans.

-

Cost: Piezo actuators and their control systems are expensive, especially for high-precision models. The use of advanced crystalline materials (PZT) and potentially hazardous elements like lead further adds to the cost.

-

Complexity: Operating piezo controls can be intricate, requiring specialized knowledge and expertise.

While piezo actuators excel in precise positioning, their limited travel range, lower bandwidth, high cost, and operational complexity make them less suitable for applications requiring larger movements, high speeds, or operation in environments with vibrations. Consider alternative solutions like DOF-5 Objective Focusing Stages with voice coil motors for these scenarios, which offer greater travel range at a lower cost.

-

Travel range: How far does the stage need to move vertically? Z stages have varying travel ranges, from micrometers to millimeters.

-

Resolution and accuracy: How precisely do you need the stage to position itself? Consider the smallest movement required for your application.

-

Speed: How fast does the stage need to move? Some Z stages prioritize speed, while others prioritize precision.

-

Load capacity: How much weight will the stage need to support?

-

Stiffness: How much force can the stage resist without deflecting? This is important for applications that require high precision.

-

Environmental factors: Will the stage be used in a cleanroom, or will it be exposed to dust, vibrations, or other contaminants?

-

Cost: Z stages can range in price from a few hundred dollars to several thousand dollars.

-

Control system: How will you control the stage? Some stages come with built-in controllers, while others require separate controllers.

By considering these factors, you can narrow down your options and choose a Z stage that is well-suited for your application.