Dover Motion Revolutionized 3D Metrology with Innovative XY Stage Design

Meeting cutting-edge performance demands with a sleek, user-friendly, and fully integrated motion solution.

At a Glance

A leading metrology equipment manufacturer sought a high-performance motion stage for a next-generation 3D optical measurement system. Their requirements went beyond just precision; they needed a compact, user-friendly, and aesthetically refined solution with zero exposed cables or motors. Traditional XY stages on the market simply couldn't deliver.

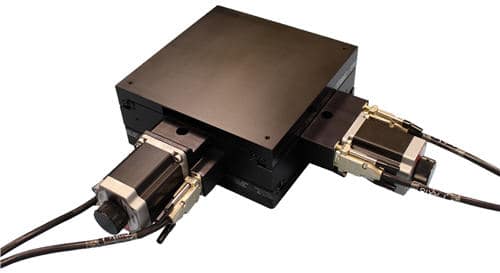

Dover Motion responded by engineering a fully integrated, monolithic XY stage with embedded motors, enclosed wiring, and optional onboard control electronics—all within a sleek, black-anodized housing. This innovative design not only met the customer’s demanding specifications but also launched a new category of XY stages: the XYA series.

To date, Dover Motion has successfully shipped over 700 units of the XYA series, demonstrating its widespread adoption and proven reliability.

The Challenge: Beyond Off-the-Shelf Limitations

A leading company in 3D optical metrology faced a significant hurdle: conventional XY stages fell short of their demanding requirements. They needed a solution that was not only robust and precise but also compact, safe, and seamlessly integrated into their advanced system. The limitations of existing stages included:

- Bulkiness: Off-the-shelf XY stages were too large, featuring external motors and exposed cabling.

- Safety Risks: Open pinch points pose hazards to operators.

- Performance Issues: Limited stiffness and precision, especially at travel extremes.

- Lack of Integration: No available solution offered integrated controls or an elegant, finished design.

- Aesthetics Mattered: The XY stage needed to be aesthetically pleasing as it would be fully visible to end customers.

The Solution: Engineering Elegance and Performance

Dover Motion collaborated intensively with the client, meticulously defining their application needs and establishing a comprehensive set of design goals. The vision was clear: create an XY stage where the stepper motors, lead screws, and all associated wiring and control circuitry were fully embedded within a minimal footprint, with only a single, unobtrusive cable connection. Beyond the technical demands, the stage needed to be exceptionally stiff for high-magnification optical applications, aesthetically sleek, and inherently safe.

Integrating for Innovation

Our team utilized compact stepper motors with integrated lead screws to significantly reduce the stage's overall size. By embedding these motors within the stage structure, all wiring was concealed, exiting discreetly from the bottom. This innovative approach also allowed for the client's control and stepper drive board to be integrated directly into the stage, further simplifying the instrument's design and enhancing its sleek appearance.

Designed for Safety and Usability

Crucially, the design incorporated custom covers that eliminated exposed motors, lead screws, wires, and potential pinch points, ensuring maximum operator safety. When centered, the entire stage presents as a clean, aesthetically pleasing black anodized block. To further enhance usability, Dover Motion included a machined grid pattern on the upper table for easy setup and part placement, along with tapped holes for additional fixture attachment points.

The XYA Series

Embedded Stepper Motors - No protrusions; motors are fully enclosed within the frame

Internal Lead Screws & Wiring - All components sealed inside; single bottom-exit cable

Integrated Control Electronics - Optional onboard controller for streamlined connectivity

Exceptional Stiffness - Rigid construction for high-magnification optical applications

Safety-First Design - No exposed mechanics; zero pinch points

Aesthetic Form Factor - Sleek black-anodized aluminum with clean, geometric contours

“Dover Motion’s design eliminated clutter and cabling challenges while delivering the stiffness and compactness we needed. It’s changed the way we design instruments.”

— Lead Systems Engineer, Metrology OEM

Explore the XYA Series

The original 100 × 100 mm travel stage perfectly met the customer’s technical and industrial design goals.

Based on this success, Dover Motion transitioned the solution into a standard product line: the XYA Series. Now combined with a SmartStage stepper motor motion control board, these stages are fully compatible with our Motion Synergy™ software platform, enabling precise control, rapid integration, and powerful characterization tools right out of the box.

The XYA is now available in:

- 100 x 100 mm travel (linear encoder optional)

- 200 × 200 mm travel (linear encoder optional)

- 200 × 325 mm travel (linear encoder optional)

These stages have since been adopted by multiple OEMs in optical instrumentation, biomedical systems, and semiconductor metrology for their ability to combine high performance with compact, integrated design.

Key Technical Specifications

Design Features Tailored to Metrology

- Machined Grid Plate: Precision reference marks for easy setup and part alignment

- Tapped Mounting Points: Flexible fixturing under the metrology head

- Black-Anodized Aluminum Finish: Reduces reflections and supports optical accuracy

- Integrated Control (Optional): Embeds stepper drive board within the stage, further reducing system size and complexity

Positioned for the Future

As industrial metrology evolves toward smarter, more compact, and automated platforms, the XYA offers a future-ready solution:

- Clean integration into instruments

- Streamlined assembly and service

- High-performance motion with optional closed-loop precision

- Safe, elegant design that enhances user trust and product appeal

- Compatible with the SmartStage ecosystem controls software