Motion Control Systems

Motion control systems are capable of extremely precise speed, position, and torque control. Applications, such as life science and diagnostics microscopy, which require precise positioning of samples, synchronization of separate instrument elements, or fast start and stop motion, are all perfect candidates for the use of motion control.

The performance of the motion control systems is dependent on the mechanics, motion control electronics, and software used within the system. Typically, a motion control system consists of:

- motion controller

- drive

- motor

- device for position feedback

Motion Controller

A motion controller is a programmable device that controls the motion path, the servo loop closure, and the sequence execution in automated motion control systems. Basically, the controller is the “brains” of the motion control system.

Based on the motion requirements, the motion controller establishes the motion trajectory, sends control signals to the drive circuit to “drive” the motor, and in a closed loop system compares the actual position feedback signal from the encoder to the commanded trajectory, and uses the control loop to take corrective action if needed, ideally with little or no error.

Drive

Depending on the motion control system, either the main motion controller or drive utilizes position feedback devices such as resolvers and encoders to achieve high precision motion tasks. The drive receives low power signals or commands from the controller and then converts those signals to a high power signal that the motor needs to operate.

To do this, the drive (which supplies power to the motor) will vary output current to the motor to induce it to rotate or move linearly at a particular speed and direction. Think of this like the “muscle” needed to power the motor.

Motor

Motors perform tasks in motion control systems. Think of this like “hands” in our body metaphor. The motor converts the electrical energy to mechanical energy to power the system. There are three types of motors commonly used in precision motion control systems: Stepper, Servo, and Piezoelectric (also known simply as “Piezo”).

- Stepper Motor: A type of motor featuring two or four stator coils and a toothed permanent magnet rotor, which moves through a small angle (typically 1.8 degrees for 200 counts per revolution or 0.9 degrees for a 400 count per revolution motor) in response to a specific sequence of coil current changes.

- Servo Motor: A DC motor which produces a torque proportional to current. Precise positioning is achieved by linear analog or PWM (duty cycle) control of motor current or voltage, together with accurate monitoring of position via an external feedback device.

- Piezoelectric Motor: A motor that uses the inverse piezoelectric effect of varying voltage to shrink or expand a piezoelectric material to induce motion. This method converts the electrical energy into mechanical energy.

Feedback Systems

Optical Encoders are used for a majority of precision motion control applications. An encoder readhead sends light, typically in the visible or IR spectrum towards a scale with a diffraction grating. The reflected light from the grating is then processed by the encoder readhead detector and the pulses are used to determine changes in position between the encoder readhead and the scale.

Laser interferometers provide the ultimate in position feedback, combining very high resolution, non-contact sensing, high update rates, and intrinsic accuracies of 0.1 ppm.

They can be used in positioning systems as either passive position readouts, or as active feedback components in a position servo loop. Unlike linear optical encoders, the interferometer beam path can usually be arranged to coincide with the item or point being measured, eliminating, or greatly reducing errors due to Abbé offset.

Discover Our Innovative Motion Control System

”Dover Motion is more than a lot of companies, pushing the boundaries of developing new ways of executing motion, and seem creative in that way.“

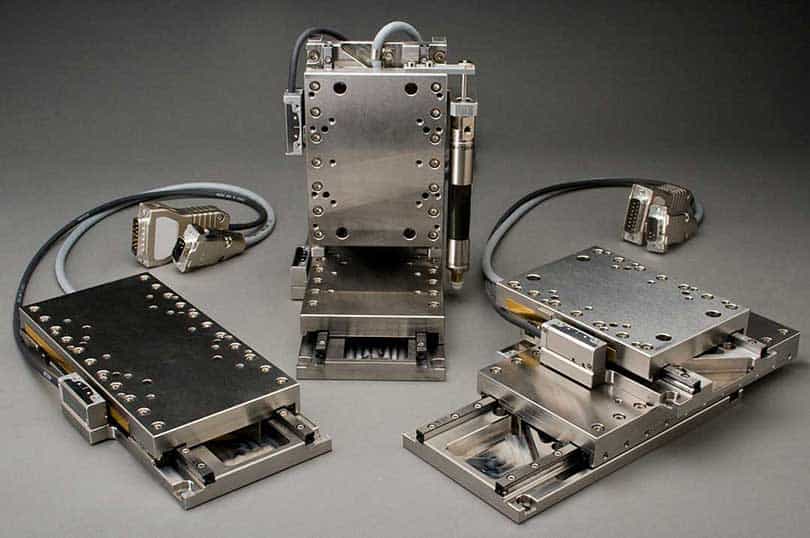

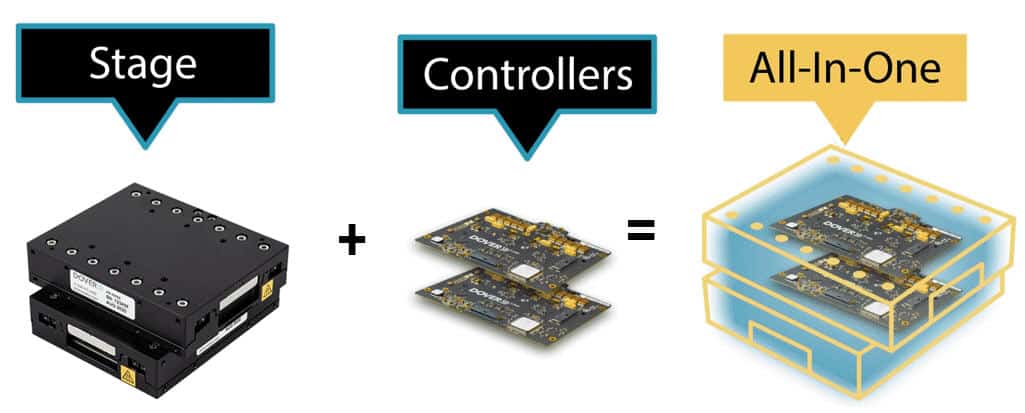

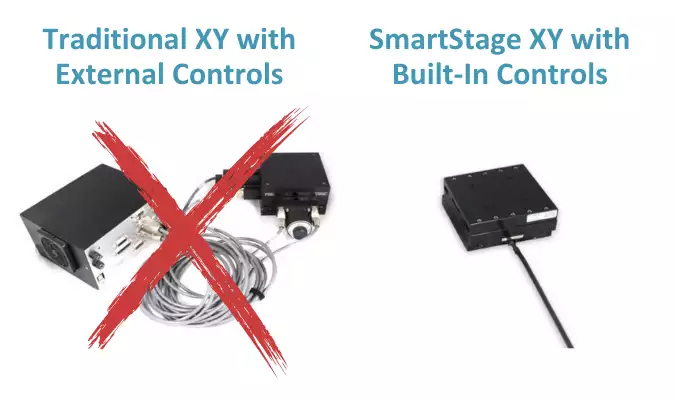

Motion Control System Technology with All-In-One Controller Built-In

Key benefits of Dover Motion’s all-in-one package with SmartStage Controller built in:

- Reduced complexity, from 4 cables for XY to only 1

- Just supply power and communications

- High Precision feedback with 5nm resolution encoder

- Reduce XY footprint by up to 400%, eliminate external motion controllers, and save space in your instrument

- Compatible with Motion Synergy™ API - all-in-one motion control software API and user interface solution

SmartStage and DOF Advanced Motion Control System Features

- Easily drive the DOF from an autofocus sensor via noise-free digital signals, in Step-Direction or A-quad-B formats, for continuous tracking objective focusing.

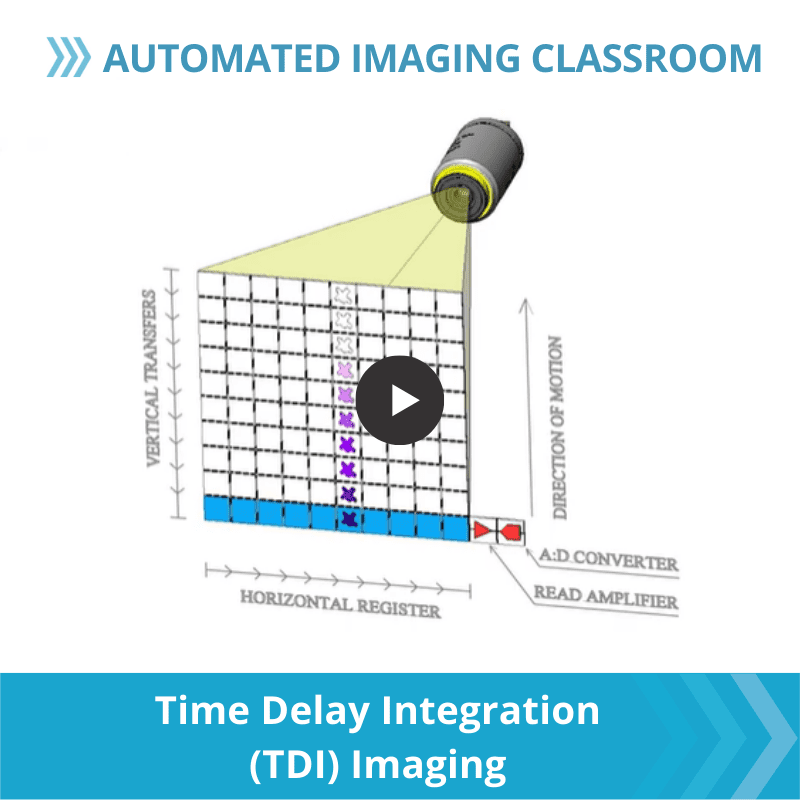

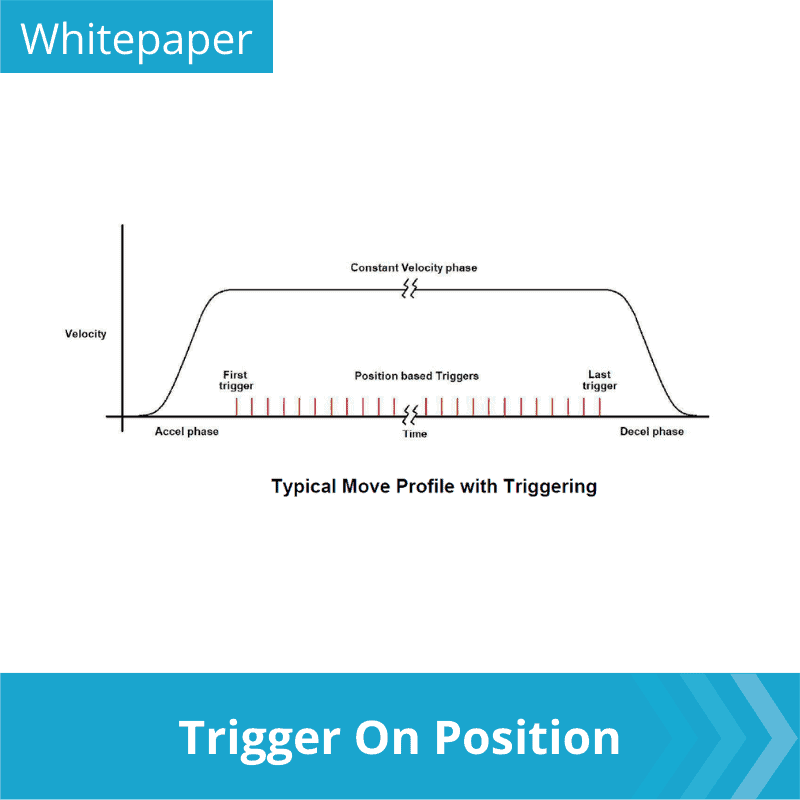

- SmartStage XY product’s built-in Trigger On Position (TOP) output facilitates precise synchronization of a camera, laser, or other peripheral device with stage position. This high speed triggering is ideal for TDI Scanning microscopy applications.

- The DOF and SmartStage XY support synchronized motion between axes.

- Stage Accuracy Compensation (SAC) provides accurate positioning at the user’s point of interest, negating Abbe and other trajectory-based errors.

- Dover Motion’s proprietary Repetitive Motion Enhancement (RME) algorithm improves step and settle performance for significant throughput gains.

Motion Synegy™ API Software

Software development does not have to take much of your budget and time. We’ve developed Motion Synergy API software that is compatible with Dover Motion’s products. It features:

- Out of the box programmable interface for rapid development

- Robust supported libraries

- Multiple interface options including .NET, C++, Python, LabVIEW, LUA scripts

- Compatible with Windows 10, Windows 11, Linux Ubuntu 22.04 LTS, Linux Ubuntu 20.04 LTS

- Built in logging and sample programs

Custom Motion Solutions

- Quick modifications tailored to your specific needs