Motorized Rotation Stages

A motorized rotation stage is an advanced positioning device that achieves precise rotational movement around a central axis, often incorporating an open aperture for optical pathways or mounting flexibility, and leveraging high-performance motor systems like stepper, DC, or direct-drive motors to enable smooth, controlled motion. Common applications include life science and diagnostics, such as imaging system alignment, rotational positioning for DNA sequencing, sample manipulation in microscopy and spectroscopy. Explore Dover Motion’s motorized rotation stages below.

Motorized Rotation Stage Products

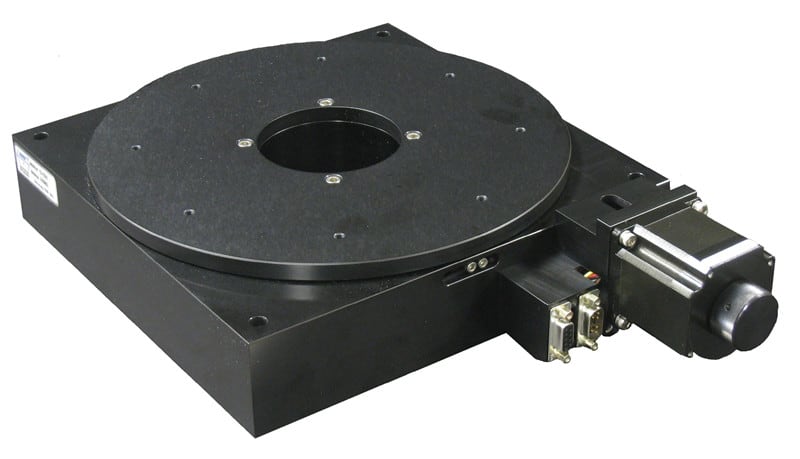

The RTR™ series motorized rotation stages are available in multiple diameters and use a precision worm gear drive for stiff angular positioning and are suitable when the payload is offset.

| wdt_ID | Travel | 360 degrees |

|---|---|---|

| 1 | Accuracy | 0.05 degree |

| 2 | Repeatability | 0.005 degree |

| 3 | Payload | 45 kg |

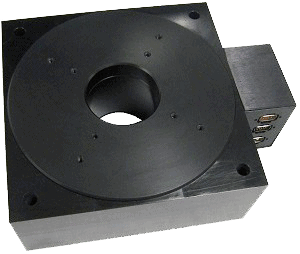

The DRT-100 and DRT-200 are ultra-compact, direct-drive rotary stages recommended for applications requiring the highest speed and precision.

| wdt_ID | Travel | 360 degrees |

|---|---|---|

| 1 | Accuracy | +/- 150 urad |

| 2 | Repeatability | +/- 5 urad |

| 3 | Payload | 100 kg |

Why Choose Dover Motion for Motorized Rotation Stages?

At Dover Motion, we specialize in providing advanced motion control solutions that excel in performance, reliability, and adaptability. Our motorized rotation stages have the following features:

- High Precision: Achieve angular accuracy up to ±0.05 degree and repeatability as fine as ±0.005 degree.

- Durable Design: Featuring rigid crossed roller bearings and anti-backlash mechanisms for consistent performance.

- Wide Payload Range: Our stages can handle payloads from delicate samples to heavy components, up to 100 kg.

- Compact Direct Drive Options: For applications where space and speed are critical, our ultra-compact direct drive stages deliver both.

- Custom Solutions: Work with our engineers to design motorized rotation stages tailored to your project requirements.