Rotation Stages, Rotary Stages

A rotation stage, also known as a rotary stage, restricts motion to a single axis of rotation and precisely controls the circular position for that axis of rotation. Dover Motion offers a range of standard high precision rotary stages and rotary tables, though our core strength is collaborating with our clients to configure the right precision motion solution for their unique application.

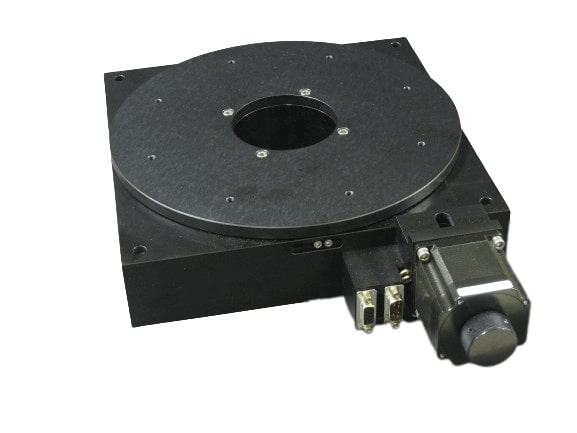

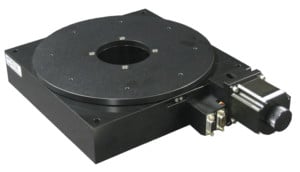

Our RTR™ precision rotary stages are equipped with stiff crossed roller bearings and a precision worm gear drive to ensure outstanding angular accuracy and repeatability. Our DRT™ series stages utilize the direct drive technology and offer ultra-compact design.

Rotation Stage Products

The RTR™ series precision rotation stages are available in 4-, 6-, 8-, 10-, and 12-inch diameter that include a preloaded, anti-backlash drive assembly to provide exceptional angular accuracy and repeatability.

| wdt_ID | Travel | 360 degrees |

|---|---|---|

| 1 | Accuracy | 0.05 degree |

| 2 | Repeatability | 0.005 degree |

| 3 | Payload | 45 kg |

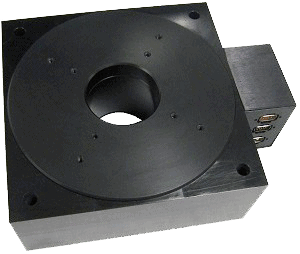

The DRT-100 and DRT-200 series direct drive rotation stages are ultra-compact, direct-drive rotation stages that establish a new level of price, performance, and size.

| wdt_ID | Travel | 360 degrees |

|---|---|---|

| 1 | Accuracy | +/- 150 urad |

| 2 | Repeatability | +/- 5 urad |

| 3 | Payload | 100 kg |

Additional Rotary Stage Resources

FAQ

Rotary motion, also referred to as theta, rotational motion or circular motion, occurs when an object rotates or spins about an axis. This type of motion is analyzed in much the same way as linear motion. The motion may be uniform or non-uniform, but it must be circular.

When a stage is referred to as having uniform rotary motion, this means that the moving table’s velocity and direction of motion is constant. Rotation stages can have variations in their rotary motion, however. For example, inertia can influence rotary motion in certain ways. Objects that have lots of inertia will require much more energy to change their velocity or position and require more motor torque.

Rotary motion is perhaps the most common and important types of motion and also the most widely used in every part of our daily lives.

The rotary stage, also called the rotation stage, is a precision motion device designed for applications that demand the highest levels of precision and accuracy in positioning. These stages are perfect for tasks like precisely rotating a delicate sample under a microscope, even by tiny fractions of a degree. They often feature advanced bearing systems, such as air bearings, to minimize friction and vibration.

Rotary stages are available in two primary types:

- manual rotary stages, which use hand-operated knobs or micrometers for precise but non-automated adjustments

- motorized rotary stages, which are equipped with electric motors for automated, programmable, and highly accurate rotational motion.

High-resolution encoders provide incredibly detailed feedback on the motorized stage's angular position. Sophisticated control systems allow for precise programming and execution of complex movements. These stages are commonly used in life science and diagnostic instruments, metrology (the science of measurement), micromachining (creating tiny components), optics alignment, and other fields where precise rotational positioning is critical.

Our motorized rotary stages use a variety of bearing and actuator technologies. For very stiff angular positioning at low to medium speeds, we use precision lapped worms and worm gears driven by a stepper or servo motor. Worm gear drive is especially valuable if the payload is offset and the system experiences a static torque. For the highest speed and precision, we recommend direct drive rotary tables such as our DRT series.

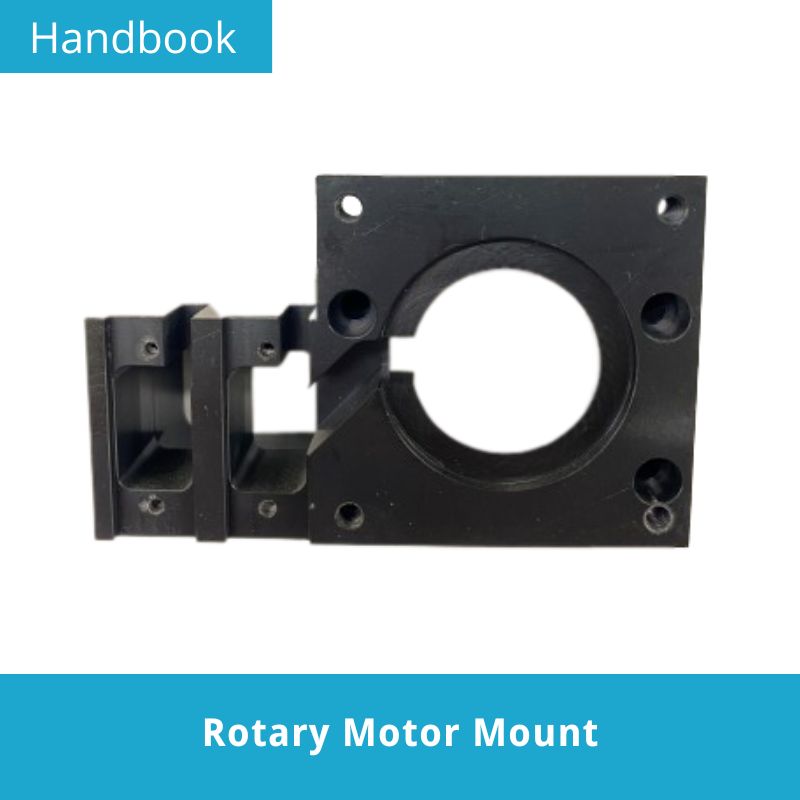

A rotary stage is a device that provides precise rotational movement for a workpiece or sample. It typically consists of a platform that rotates, a drive mechanism, and a bearing system. The platform is where you mount the object you need to rotate. The drive mechanism provides the force to turn the platform. Motorized drives offer greater precision and the ability to program specific movements. The bearing system ensures smooth, accurate motion with minimal friction or wobble. This is critical for achieving the precise positioning required in many applications. Some rotary stages also incorporate feedback devices, such as encoders, to provide precise position information, allowing for closed-loop control and highly accurate positioning.

Precision in rotation refers to the ability of a rotary stage to achieve and maintain a desired angular position with minimal error. It's about how accurately and reliably the stage can move to a specific angle and stay there. This is quantified by several parameters, including:

- Accuracy: How close the actual position of the stage is to the commanded position.

- Repeatability: The ability of the stage to return to the same position multiple times.

- Resolution: The smallest increment of rotation that the stage can reliably achieve.

High-precision rotary stages are essential in applications where even minor angular deviations can significantly impact the quality or performance of the task at hand. For example, in fluorescence microscopy, a tiny error in rotation could lead to inaccurate localization of fluorescent molecules, compromising the analysis of cellular structures and processes.

While our rotary stages can be used as complete single-axis positioners, in many cases they are integrated with additional linear or rotary axes. A common example is to add a rotation stage to the top of an XY stage. In this case, it is important to consider the total range of travel. For applications where the payload must be aligned after loading it onto the stage stack, a limited travel of +/- 5 degrees may be sufficient. In other applications, 360-degree or unlimited rotation may be required.

Rotary stages, including high precision rotary stages, can also be mounted to each other, allowing the customer’s part to be rotated in multiple axes. In one such example we designed a stack of three rotary tables that was used to move a miniature spherical laser fusion target in three rotational degrees of freedom during laser micromachining.

No, our standard motorized rotary stage has only 1 limit switch. The switch is typically wired to pin 2 on the limit encoder connector. The limit switch is intended to be used for homing. The homing routine will work with an initial positive or negative jog move of the motorized rotary stage until the limit switch triggers. If an encoder is also used, the home or zero position can then be set at the point where the limit switch is triggered.