Precision Liquid Handling

Automated Liquid Handling

Automated liquid handling is a core technology that enables much of modern life sciences and diagnostics. Its basic operations are:

- Aspiration: drawing liquid upwards into a pipette

- Motion: moving to a new location

- Dispensing: expelling the liquid into a new container

Typical life science and diagnostics applications that require precision liquid handling include:

- Genomic sample prep

- High-throughput screening

- Aliquoting

- Immunoassays

- Polymerase chain reaction (PCR) amplification

When and Why to Use Automated Liquid Handling

Biochemical protocols require a lot of pipetting. Many labs use manual pipettes, but increasingly automation has been introduced to

increase both throughput and reliability. In automated liquid handling systems, the pipette is programmable and 3 axes of motion are added to allow one or more pipettes to flexibly move liquids from one container to another.

Choosing Positioning Components

Dover Motion offers a range of motion technologies for precision automated liquid handling, from simple open-loop stepping motors with lead screws, to direct drive positioners based on linear motors and encoders. There are a number of requirements for the positioning components in an automated liquid handling system. These include:

- High speed: to increase throughput

- Precision: to ensure accurate delivery to the target well

- Jerk control: to avoid any droplets going astray

- Quiet and reliable operation

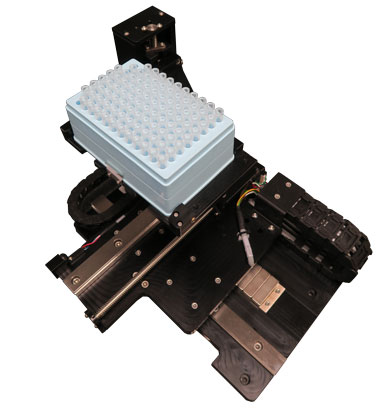

Belt-driven motion dominates the life science and diagnostics markets and Dover Motion has extensive experience developing these sorts of liquid automation systems, including the three-axis liquid handling robot in Figure 1.

Direct drive technology is normally associated with larger structures and budgets, but we have driven its size and cost down to the point where this technology now approaches the same price point of traditional positioning solutions. The advantages of direct drive include whisper-quiet operation at high speed and high acceleration, as well as a very long service life with high reliability, higher precision, and lower support costs.

Other Available Technologies

In addition to our expertise in precision motion, Dover Motion has developed a number of ancillary technologies related to liquid handling automation. These include:

- Miniature, direct drive liquid and air displacement pipettors

- Independent 8, 12, or 16 pipette motion system on 9 millimeter pitch

- High-speed liquid dispensing, at as low as 100 picoliter volumes

- Integrated temperature control for protocols requiring thermal cycling

- Flow cell design, including fine-pitch patterned binding sites

Building the Right Motion Solution

It’s common for the right positioning solution to require more functionality or specifications than that of an off-the-shelf robot. In many of our clients’ automated liquid handling projects, the liquid handling function is required as part of a dedicated life science or diagnostics system that performs a number of other tasks. And oftentimes the available space within the instrument is highly constrained by other system components.

We specialize in collaborating with our clients to configure the right motion solution for their unique application. Contact us today to learn about how we can work together on your next automated liquid handling project.

Related Products

Precision Liquid Handling Products

The DOF™ microscope stage is optimized for objective focusing with increased travel, higher bandwidth, and lower cost than piezo stages.

| wdt_ID | Travel | 5-9 mm |

|---|---|---|

| 1 | Resolution | 1.25 nm |

| 2 | Repeatability | < 50 nm |

| 3 | Bandwidth | > 225 Hz |

The award winning SmartStage™ XY stage offers high precision and includes an embedded controller inside the stage.

| wdt_ID | Travel | 50 - 200 mm |

|---|---|---|

| 1 | Accuracy | ≤ 10 μm |

| 2 | Repeatability | 0.8 μm |

| 3 | Payload | 10 kg |