Automating Precision Assembly with the SmartStage™ XY

At a Glance

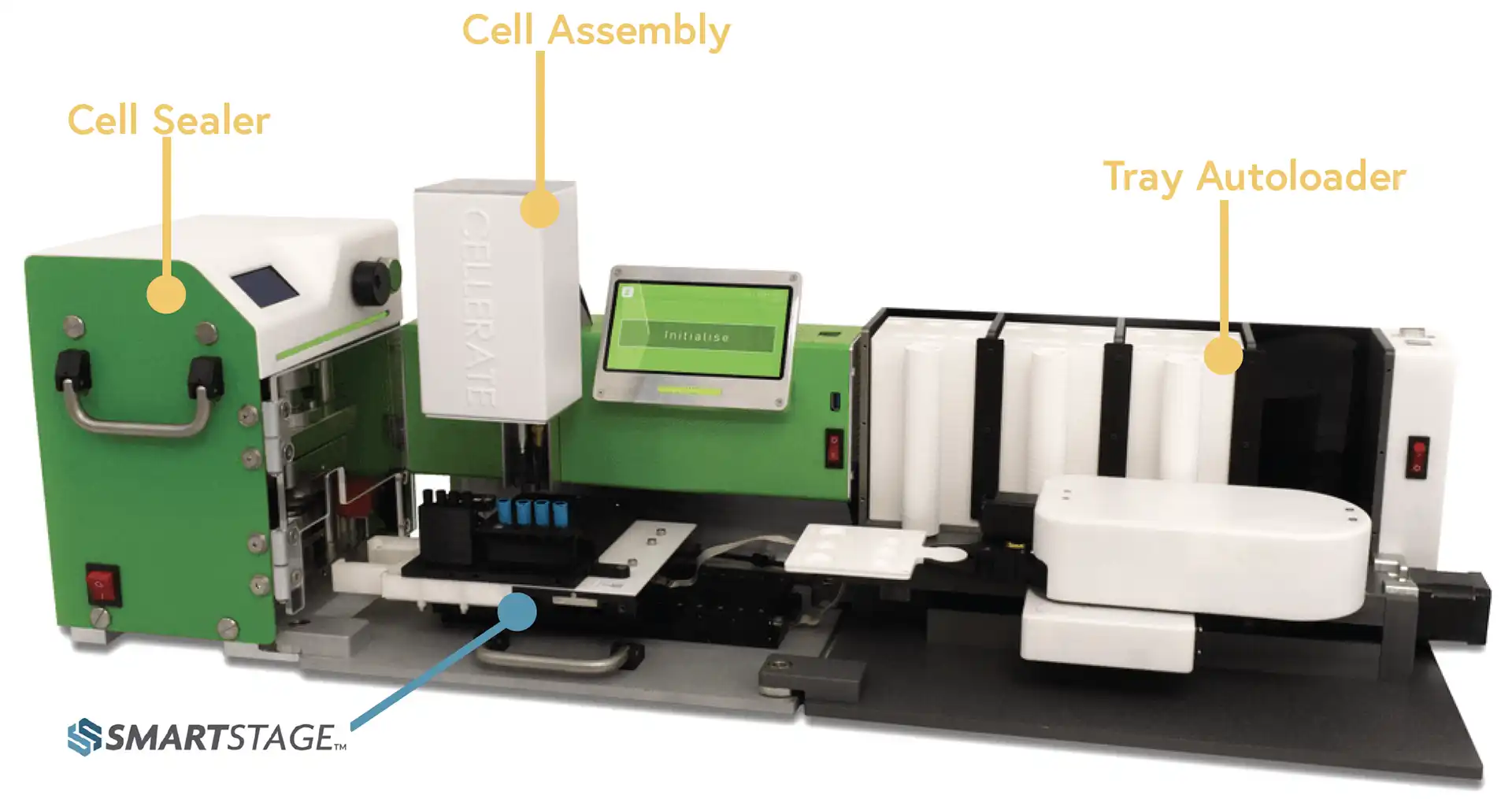

The Cellerate System for Automated Battery Cell Assembly and Sealing provides breakthrough precision automation for battery test cell assembly. Used for both coin and pouch battery formats, this technology increases accuracy, multiplies operator bandwidth and increases data insight across research, development and quality control workflows.

The innovative Cellerate Assembly Module is enabled by the Dover Motion SmartStage XY platform in order to achieve repeatable assembly accuracy within a condensed package.

Automating Tedious Cell Assembly

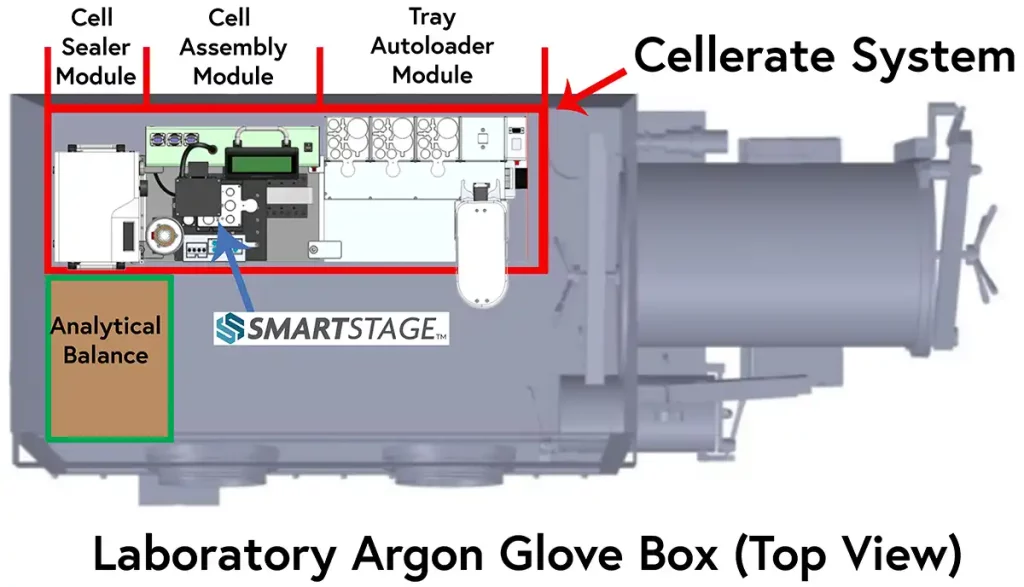

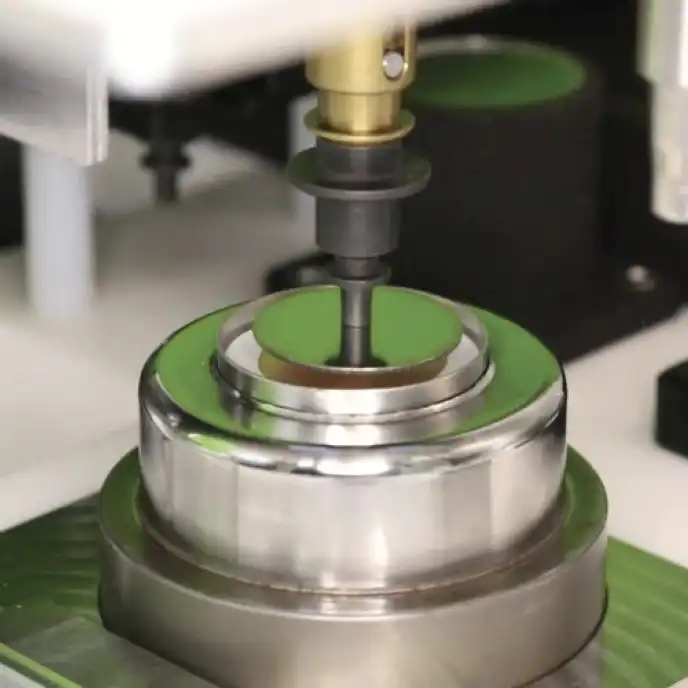

The defacto standard for building battery test cells relies on operators manually assembling cells inside of a laboratory glove box. Today, the Cellerate System uncouples people from this tedious and repetitive work so they can focus on research, development and quality control. The Cellerate System is comprised of three modules inside of the glove box: the Tray Autoloader, the Cell Assembly and the Cell Sealer. One person loads material and programs an automated run for up to 100 test cells. The assembly module, with the SmartStage XY central to the motion, provides 50 µm (or better) assembly alignment accuracy and records the assembly data. The operator has data validation, images and completed test cells at their fingertips. Now one operator can support multiple projects within a work day instead of being fully consumed by a single build.

Goal

Develop a modular automation platform that enables the unattended assembly of battery test cells inside of a Laboratory Argon Glove Box.

Challenge

Modules must fit within a standard two-port glove box, be able to pass through the air lock chamber and maintain component placement accuracy of 50 µm or better.

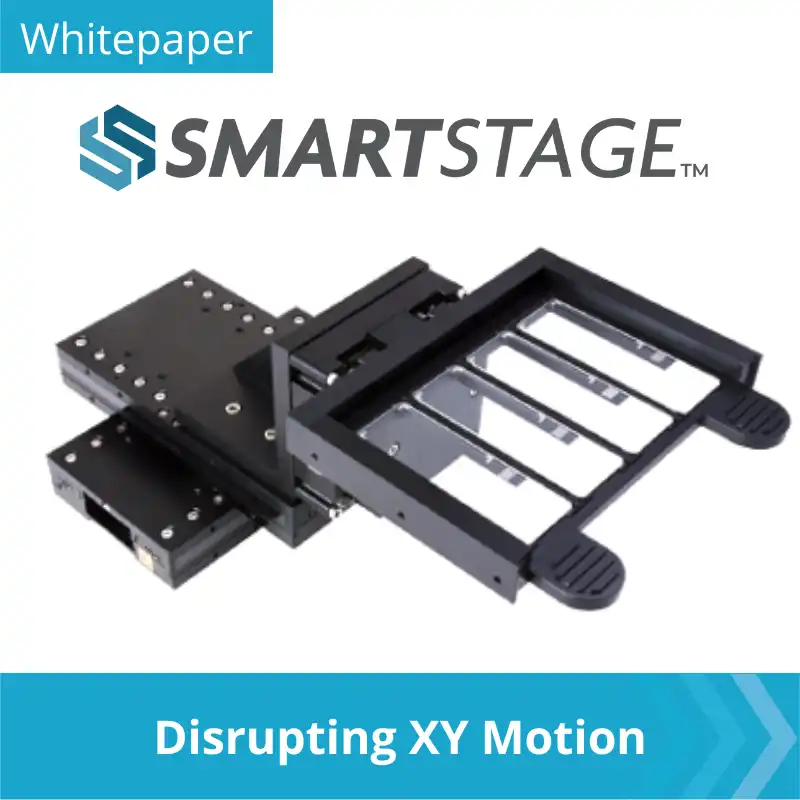

The Cellerate Assembly Module with the SmartStage XY

The Cellerate modules present a challenging trade-off for the traditional stepper motor and screw driven technologies: increasing accuracy while decreasing size. This is why Cellerate selected the Dover Motion SmartStage™ XY Direct Drive Linear Stage. With the SmartStage XY at the core of the motion platform, Cellerate was able to achieve the following:

85% reduction of manual touch time

Simplified installation through antechamber

Alignment within 50 μm or better

Repeatable and Compact XY Motion

Each Cellerate module system can assemble up to 100 test cells in one unattended operation. It turns 8 hours of touch time into only 1 hour. The high resolution and repeatability of the SmartStage™ XY allows the Cellerate Assembly module to have repeatable component alignment of 50 µm or better. The HD image verification at the assembly step provides proof of component alignment for quality control.

The SmartStage XY has controllers on board which eliminates the challenge of mounting bulky external controls. This allows Cellerate to decrease their systeminto a package that can fit into the average 1400 mm x 700 mm laboratory argon glove box. The onboard electronics also reduces the number of cables for the system, which pass neatly through the rear KF-40 ports. The Cellerate Modules can pass through the vacuum antechamber, preventing an off-cycle purge and refill of the glove box during system installation and service.

The Cellerate Module System can be used across the entire battery testing ecosystem: from fundamental battery research up to production quality control. This innovative system provides reliable cell assembly and seamless data transfer between departments and organizations.

“Cellerate is truly the breakthrough that the coin and pouch battery industry was craving. Thanks to the Dover Motion SmartStage™ XY, we were able to meet and exceed our repeatability requirements within compact, glove box-compatible module.”

Saving 100,000+ Hours Per Year

Scientists spend over 100,000 hours per year building test cells manually inside of a glove box. With the SmartStage XY central to the Cellerate Assembly Module motion, these saved hours will translate into shorter product development times and accelerate discoveries across all stages of battery design including battery research, development and quality control.

“We were excited about at how easy it was to integrate the SmartStage™ XY with its onboard controls into the Cellerate Assembly Module – our very first system was up and running in a little over a week.”

Smart Stage XY Mechanical Information

* Other resolutions available, for options contact an applications engineer

*1 Accuracy has 2 point slope correction applied

*2 Please contact our Applications Engineers for loads exceeding 10kg.

*3 The maximum acceleration and velocity is resolution and load dependent.

*4 Linear stage must be mounted to a flat surface, see datasheet for details

The Cellerate System Size