Positioning Stages

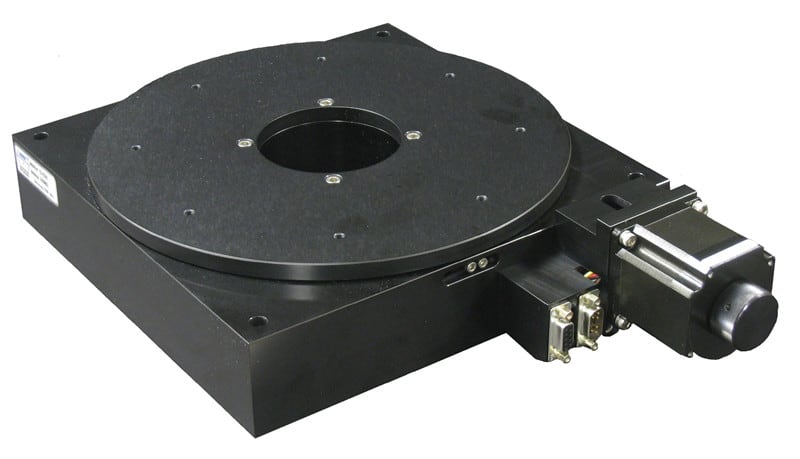

For more than six decades, Dover Motion has engineered high-precision positioning stages for microscopy, metrology, photonics, and industrial automation applications. Our portfolio includes linear positioning stages, rotary positioning stages, XY positioning stages, and Z-axis stages, all designed to deliver smooth, accurate, and repeatable motion. Positioning stages can be configured as standalone solutions or integrated into multi-axis motion systems with our advanced controllers.

What is a positioning Stage?

A positioning stage is a precision mechanical device engineered to move and position objects with high accuracy along one or more axes, including linear, rotary, or angular motion. These stages feature advanced components such as ball screws, crossed roller bearings, and precision guide rails to ensure smooth, repeatable movement with minimal backlash and high load capacity. Often equipped with micrometer drives or motorized actuators, positioning stages are critical in applications like microscopy, metrology, optics, and precision assembly, enabling controlled movement with nanometer accuracy and exceptional stability under varying loads.

Types of Positioning Stages

Linear positioning stages are available in various types to fit specific applications and performance requirements. Based on the method of actuation they can be classified into:

- Manual Stages: Operated by hand, often using micrometers or lead screws for precise, low-speed adjustments. Ideal for applications where infrequent and controlled manual positioning is sufficient.

- Motorized Stages: Driven by stepper or servo motors, these stages provide automated, high-precision motion and are well-suited for tasks requiring frequent, repeatable positioning or integration into automated systems.

Linear positioning stages can also be classified by the type of bearings they use, which directly impacts their precision, load capacity, and motion smoothness. Below are the four main types:

- Crossed Roller Bearing Stages

Designed with precision-engineered crossed roller bearings, these stages offer high rigidity, low friction, and excellent accuracy. They are suitable for applications requiring reliable movement under heavy loads, such as industrial automation and materials testing.

- Ball Bearing Stages

Utilizing recirculating ball bearings, these stages provide smooth motion and high load capacity, making them ideal for medium-precision tasks like general laboratory setups or industrial assembly lines.

- Air Bearing Stages

These stages use a cushion of pressurized air to eliminate mechanical contact, resulting in ultra-smooth, frictionless motion. They are the preferred choice for high-precision applications such as metrology and semiconductor wafer inspection.

- Plain Bearing Stages

Employing sliding contact surfaces, plain bearing stages are cost-effective and durable but have higher friction. They are often used in applications with lower precision demands and lighter loads.

- Piezoelectric Stages (Flexure Bearings)

Featuring flexure bearings in conjunction with piezoelectric actuators, these stages deliver high levels of precision without mechanical play.

Positioning Stages Resources

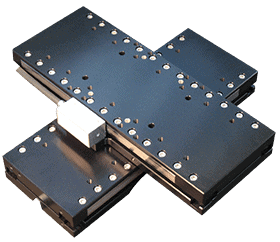

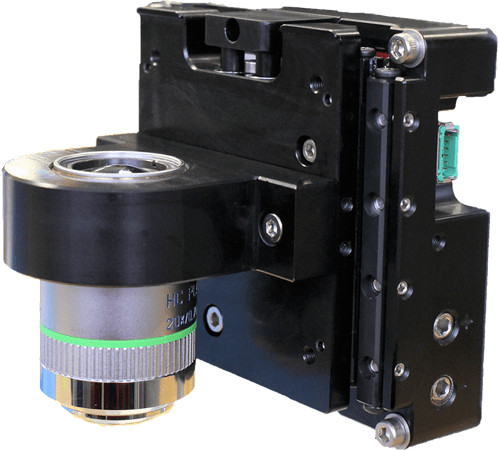

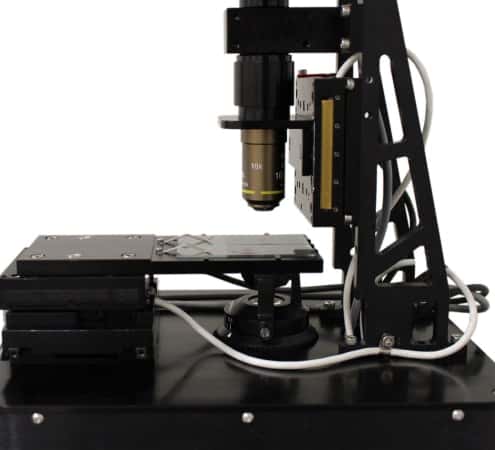

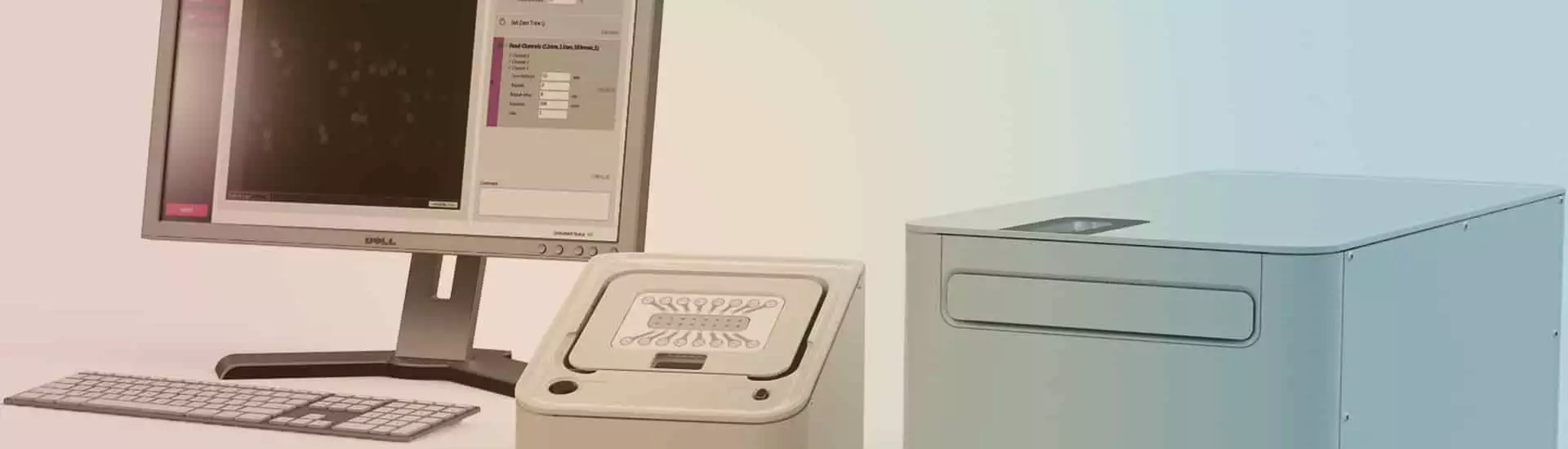

Through concurrent and collaborative engineering, Dover Motion developed a compact custom XYZ stage motion solution to produce high-precision cell imaging in parallel with the instrument design.

Dover Motion defined the motion system requirements and tightly integrated the hardware in the overall instrument design, enabling the client to get the funding they needed to continue their project.

To reduce the overall size, Dover Motion used compact stepper motors with integrated lead screws. Placing the motors within the stage structure enabled all wiring to be concealed and to exit at the bottom of the stage.