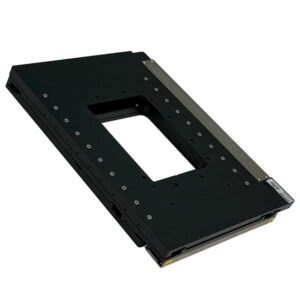

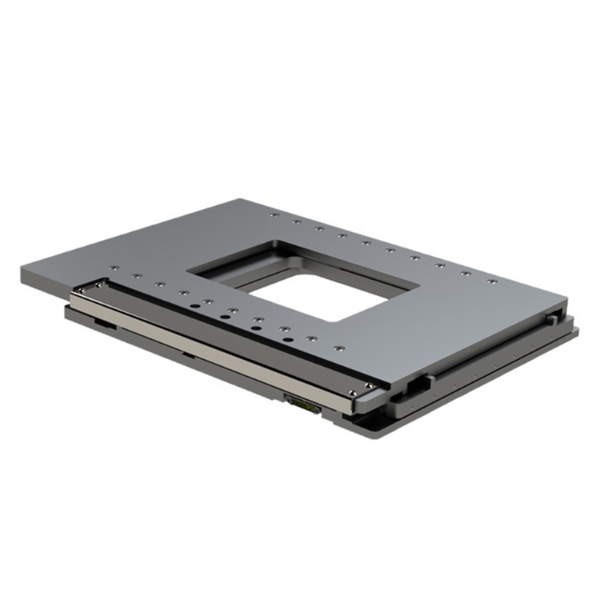

SmartStage™ Open Frame XY with Built-in Controller

The SmartStage™ Open Frame xy scanning stage, is the first open aperture linear motor stage with an embedded controller physically integrated inside the stage structure providing increased performance and simplified integration.

Benefits of a SmartStage™ Open Frame XY

-

ALL controls inside; ONE external cable

-

Easy for prototyping

-

Cost-effective for production

Specifications

SmartStage™ Open Frame XY Scanning Stage Specifications

| wdt_ID | Description | Specification | Specification |

|---|---|---|---|

| 1 | Travel (mm) | 75 x 115 mm (Available Now) | 150 x 150 mm (Coming Soon: Inquire for Details and Timing) |

| 2 | Payload Mass | up to 6 kg | up to 6 kg |

| 3 | Resolution (nm) | 5 nm | 5 nm |

| 4 | Accuracy, slope corrected (2σ)1 | ≤ 10 µm | ≤ 10 µm |

| 5 | Bi-directional Repeatability (2σ)1 | ≤ 0.5 µm | ≤ 0.5 µm |

| 6 | Minimum Move | 100 nm | 100 nm |

| 7 | Holding Stability (raw) | ± 30 nm | ± 30 nm |

| 8 | Holding Stability (RMS) | 15 nm | 15 nm |

| 9 | Maximum Acceleration no load (Y,X) | 15.0 m/s2 , 7.5m/s2 | 10.0 m/s2 , 4.1m/s2 |

| 10 | Maximum Velocity no load (Y, X) | 0.95 m/s, 0.6 m/s |

0.95 m/s, 0.6 m/s |

| 11 | Step-Settle 1mm move, +/-30 nm window | 250 ms | 250 ms |

| 12 | Flatness and Straightness (TIR) | 5 μm | 5 μm |

| 13 | Pitch & Yaw | 150 μrad | 150 μrad |

| 14 | Orthogonality | 240 μrad | 240 μrad |

| 15 | Total Mass | 6.2 kg | 11.1 kg |

| 16 | Moving Mass (X and Y) | 4.4 kg | 8.1 kg |

| 17 | Moving Mass (Upper only, Y) | 1.8 kg | 3.0 kg |

| 18 | Motor Peak Force | 33 N | 33 N |

Optional changes to accommodate well plate incubator payload available upon request

*1 Tested according to ISO230-2 standard

Additional travel sizes available soon.

Communications:

- CAN 2.0B

- RS-232

- RS-485

Description

Leveraging the proven SmartStage™ linear compact architecture and its precise motion solution capability of choice for high-performance microscopy and life science instruments, the SmartStage™ Open Frame XY scanning stage now allows you a wide travel range for your transmissive microscopy applications.

Key benefits:

- Easy design integration. Leverage a common control architecture for your motion stages, while enjoying reduced part count, size, and complexity, with all the controllers built-in, and serviced by a single cable connection per stage.

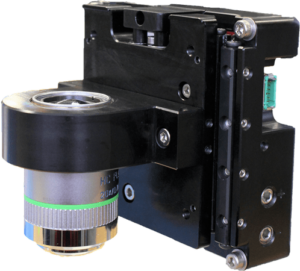

- Unique motor design provides the compact linear actuator smoother motion with industry-leading velocity stability.

Applications

SmartStage™ Open Frame XY is the product of choice for open aperture applications requiring a large travel range, combined with rapid, precise positioning of large masses.

- Optimized for regular or inverted microscopy applications that require an open aperture.

- Space savings: compact linear motor and physically integrated controller stage designed to fit inside benchtop instruments.

- Suitable for slides, well plates, (also optional accommodation for incubators available)

Support applications include:

- Next-generation sequencing (NGS)

- Digital cell morphology

- Automated digital pathology

- Optical metrology instruments

- Semiconductor and nanotechnology imaging

- Digital microscopes

- High content imaging

- Automated cell counting

High Resolution Trigger On Position for Image Capture or Laser Synchronization

- High speed hardware output with < 1 nm resolution for synchronizing stage position with a camera or laser. Ideal for triggering during motion commonly required for TDI Imaging or laser processing.

- A high-speed Trigger On Position output allows precise synchronization of a camera, laser, or other peripheral device with the exact position of the stage. Triggering is configurable at either fixed incremental intervals, or at arbitrary intervals using a user-defined look up table.

Coordinated Motion

- User defined profile mode (UDP) allows stages to coordinate motion using auxiliary inputs. Stages can be driven by another axis or external source to follow defined motion curves based off the input.

Downloads

Datasheets

Manuals

Software

Firmware

CAD Downloads

CAD Model

Request a Quote

"*" indicates required fields

* required fields

The information provided will be used in accordance with our privacy policy.

FAQ's

An XY scanning stage is an advanced precision motion platform engineered to facilitate controlled linear movement along two orthogonal axes in the X (horizontal) and Y (vertical) directions. These stages are designed to achieve sub-micron to nanometer-level accuracy and repeatability.

The construction of an XY scanning stage typically includes the following elements:

- Linear Motion Guides: Provide smooth, friction-minimized motion paths.

- Actuation Systems: Usually include stepper motors, servo motors, or piezoelectric actuators for precise control over motion.

- Feedback Mechanisms: Use encoders (optical, magnetic, or capacitive) to ensure accuracy by continuously monitoring position and correcting deviations in real-time.

- Load-Bearing Components: Materials such as aluminum, steel, or ceramic are employed to optimize stiffness, thermal stability, and dynamic performance.

There are a few key performance metrics that define the xy scanning stage. They include:

- Travel Range: The maximum distance covered along each axis.

- Resolution: The smallest incremental movement achievable, often critical for sub-micron applications.

- Accuracy: The deviation from the desired position over the full travel range.

- Repeatability: The ability to return to the same position under identical conditions.

XY scanning stages are critical in applications requiring fine motion control, including:

- Microscopy: For specimen scanning in biological or material sciences.

- Semiconductor Fabrication: For wafer inspection and lithography.

- Automated Inspection Systems: For quality control in manufacturing.

When selecting an XY scanning stage, consider these key features:

- Travel Range: The maximum distance the stage can move along the X and Y axes.

- Accuracy and Repeatability: High precision ensures tasks like microscopy are performed reliably.

- Load Capacity: Evaluate the maximum weight the stage can handle.

- Speed and Acceleration: Critical for high throughput applications.

- Integration: Compatibility with your existing system, such as motion controllers and feedback mechanisms.

The SmartStage™ Open Frame XY is an excellent solution for life science and diagnostics instruments, offering high precision and reliability. Its open-frame design is particularly suited for applications such as automated microscopy, medical imaging, laboratory automation, and sample positioning in diagnostic instruments. The adaptable design also supports advanced workflows in genetic analysis, cell sorting, and high-throughput screening.

Our motion control software, Motion Synergy™ API, streamlines setup with user-friendly tools for commissioning and seamless integration into your instrument while offering the ultimate in advanced applications and motion profile features. It supports .NET, C++, Python, LabVIEW, LUA scripts interface options, and Windows 10, Windows 11, Linux Ubuntu 22.04 LTS, Linux Ubuntu 20.04 LTS operating systems. Click here to read more.

Absolutely. The SmartStage™ Open-Frame XY can be tailored to meet specific needs, such as travel range, load capacity, and motion accuracy. Contact Dover Motion for more information on customization options.