Specifications

High Speed Linear Actuator – SAS™ Specifications

| wdt_ID | Base Model | SAS-800 | SAS-1200 | SAS-1800 | SAS-2400 | SAS-3600 |

|---|---|---|---|---|---|---|

| 1 | Travel (mm) | 200 | 300 | 450 | 600 | 900 |

| 2 | Accuracy (μm TIR) | 6 | 9 | 11 | 13 | 21 |

| 3 | Bi-directional Repeatability (± μm) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| 4 | Load Capacity (kg) | 70 | 70 | 70 | 70 | 70 |

| 5 | Maximum Acceleration (m/s2) | 50 | 50 | 50 | 50 | 50 |

| 6 | Maximum Velocity (m/s) | 5 | 5 | 5 | 5 | 5 |

| 7 | Flatness & Straightness (μm TIR) | 3 | 5 | 9 | 13 | 30 |

| 8 | Motor Peak Force (N) | 560 | 560 | 560 | 560 | 560 |

| 9 | Motor Continuous Force (N) | 171 | 171 | 171 | 171 | 171 |

| 10 | Total Mass (kg) | 20 | 23 | 27 | 32 | 38 |

Description

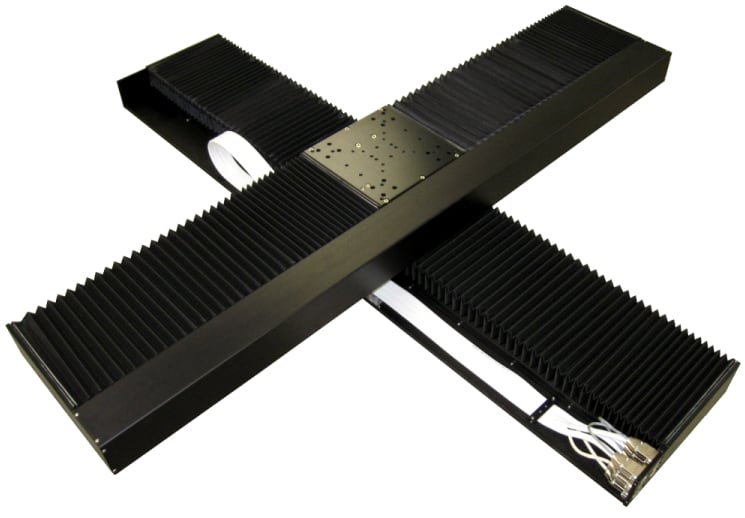

The SAS™ series linear actuators provide long travel precision positioning. This high speed linear actuator utilizes recirculating bearings to minimize the overall moving envelope. It has a direct drive servo motor that is available in both ironless and ironcore versions.

Performance is further enhanced by combining a precision linear encoder. Standard options include flexible bellows to keep particulates in the environment away from the bearings and motor. This positioning stage cabling terminates on a static base plate, simplifying external wiring for convenient integration. Pneumatics and extra signal cables can be made available upon request, and routed to the moving top plate. Two linear actuators can be conveniently stacked into an XY configuration with 15 arc-second orthogonality.

Design Features

- Ideal for scanning or step-and-repeat applications

- High speed linear servo motor

- Space saving shuttle design

Options for the SAS™ High Speed Actuator

- Motor options available: ironcore or ironless linear 3 phase servo motors

- Feedback options available: linear encoder with analog or digital feedback (digital 1 um or 0.1 um resolution are standard, other resolutions available upon request)

- Download the datasheet for additional technical details

Applications

A packaging machine OEM required multiple stage to operate precisely at high speeds to move printer heads. The SAS™ high speed actuator bellows allows the stage to work in the harsh printing/ink environment and the direct drive motor provides speeds that could not be achieved with a screw driven stage.

Downloads

Datasheets

Request a Quote

"*" indicates required fields

* required fields

The information provided will be used in accordance with our privacy policy.