Specifications

Linear Motion Slide – LM™ Specifications

| wdt_ID | Base Model | Grade | LM-200 | LM-400 | LM-600 | LM-800 | LM - 1000 | LM - 1200 |

|---|---|---|---|---|---|---|---|---|

| 1 | Travel (inches) | 2 | 4 | 6 | 8 | 10 | 12 | |

| 2 | Leadscrew Accuracy (μm) | Precision | 15 | 20 | 20 | 20 | 25 | 30 |

| 3 | Commercial | 45 | 65 | 75 | 80 | 100 | 120 | |

| 4 | Bi-directional Repeatability (± μm) | Precision | 3 | 3 | 3 | 3 | 3 | 3 |

| 5 | Commercial | 6 | 6 | 6 | 6 | 6 | 6 | |

| 6 | Flatness & Straightness (μm) | 5 | 6 | 8 | 10 | 12 | 14 | |

| 7 | Pitch & Yaw (arc-seconds) | 15 | 20 | 25 | 30 | 35 | 40 | |

| 8 | Load Capacity (kg) | 75 | 95 | 125 | 145 | 175 | 175 |

Description

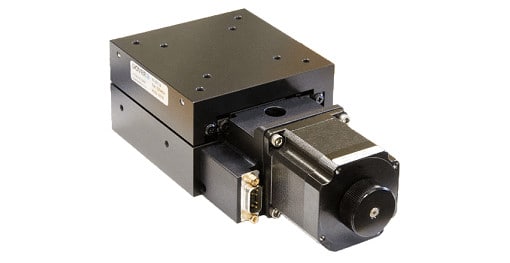

The LM™ series linear slide incorporates a lead screw for high accuracy and low cost, and comes standard with a 200-count stepper motor. For higher resolution motion, an upgrade to a 400-step-per-revolution stepper motor or servo motor is available.

We also offer an optional rotary encoder to be mounted to the lead screw shaft and provide position feedback with 2000- or 4000-count resolution. The encoder feedback provides the controller with position information to avoid open loop stepping. A manual knob to move the stage when powered off comes standard on LM™ series linear slides, along with end of travel limit switches and D-sub style electrical connectors.

The LM™ series electric linear slide positioning stage has different metric and English lead screw pitch choices depending on application resolution and speed requirements.

Applications

LM™ series linear slides are used in many applications where stepping or scanning of a part is required. Our customers are using LM™ series to move parts in laser machining equipment, or to scan the surface of magnetic media.

Downloads

Datasheets

Whitepapers

CAD Downloads

CAD Model

Request a Quote

"*" indicates required fields

* required fields

The information provided will be used in accordance with our privacy policy.