High Bandwidth Objective Focusing Stage

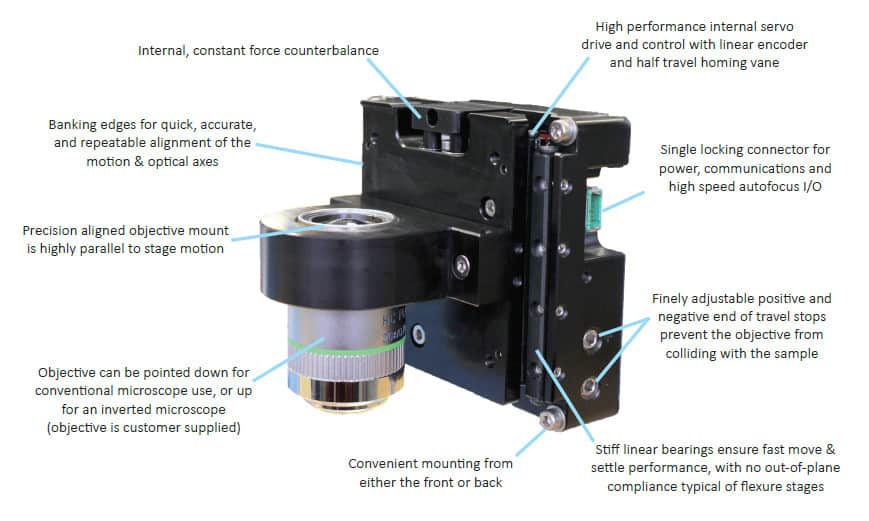

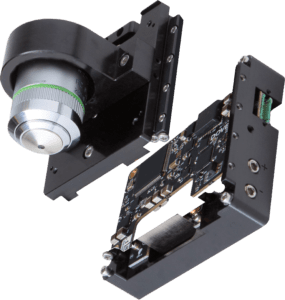

The DOF-5 objective focusing stage has been engineered to offer increased travel (5 mm) and higher bandwidth (> 225 Hz) at a fraction of the cost of piezo stages with piezoelectric motors. By embedding the servo drive and motion controller inside the stage, complex cabling has been removed resulting in a lower overall system cost than competing offerings, while still maintaining equivalent or better performance.

Benefits

- ALL controls inside; ONE external cable

- 5nm RMS Position Stability

- 25 nm Repeatability

- Easy for prototyping; cost-effective for production

Looking for a lower cost/lower resolution solution? Click here!

Specifications

DOF-5 Focusing Stage Specifications

| wdt_ID | Description | Specification |

|---|---|---|

| 1 | Travel (mm) | > 5 |

| 2 | Payload Mass (g) | 100 – 900 |

| 3 | Resolution (nm) | 1.25 or 5 |

| 4 | Servo Bandwidth (Hz) | ≥ 225 Hz |

| 5 | Stability (nm RMS) | 5 |

| 6 | Step & Settle | 100 nm within +/- 15 nm in < 15 ms |

| 7 | Bi-Directional Repeatability (nm) (for 500nm moves) | 25 |

| 8 | Homing Repeatability (µm) | 1 |

| 9 | Overall Size, excluding objective mount (mm) | 77 x 82 x 30 |

| 10 | Max Acceleration (m/s/s) with 1 kg | 6 |

| 11 | Max Velocity (mm/s) | 125 (with 5 nm resolution) |

| 12 | Communications | RS232, RS485 full or half Duplex, CAN2.0B |

| 13 | Inputs | Step and direction |

*Other resolutions available, for low numerical aperture objective options, contact an applications engineer.

Description

DOF-5 – Objective Focusing Stage

The DOF-5 objective focusing stage has been engineered to offer increased travel (5 mm) and higher bandwidth (> 225 Hz) at a fraction of the cost of piezo stages with piezoelectric motors. By embedding the servo drive and motion controller inside the stage, complex cabling has been removed resulting in a lower overall system cost than competing offerings, while still maintaining equivalent or better performance.

With > 5 mm of travel, the DOF-5 provides more engineering flexibility. The restricted travel of piezo systems (typically 100 to 300 microns) often leads to compromises in system performance. Attempts to extend the travel, such as employing lever amplification, dramatically decrease the focus stage’s resonant frequency and stiffness. The DOF-5’s increased travel removes the need for additional coarse positioning axes. In addition, the DOF-5 can be connected directly to an Autofocus system for easy integration.

DOF-5 focusing stages offer the following features and benefits:

Hardware Agility:

- Unique, compact, integrated motion stage and miniaturized controller, with a single combined power and communications cable

- Easy integration; with minimized footprint, complexity, and lower parts count inside your instrument

- Integrated solution for multiple stages

Performance:

- Precise, high-performance motion control – and supporting software tools – for the most demanding applications

- Compelling price-to-performance ratio, achieved using an innovative and patented system architecture

- Long-life: quiet brushless linear motor, non-contact encoder, crossed-roller linear bearings

Dependability:

- Reliability and confidence of an experienced supplier

- More than 22,000 motion systems shipped to Fortune 500 companies worldwide

- On-time delivery of over 95%

Integrated Solution

- By including the encoder, interpolator, drive, and motion controller electronics all within the stage, the DOF-5 is able to achieve high in-position stability and avoid noise errors introduced by external cabling, poor grounding, and other detrimental influences on the feedback signal

- Ecosystem of DOF-5 objective focusing stage and SmartStage XY provides an integrated control solution for your applications

- Simplify software architecture with common API between X,Y, and Z stages

Precision Linear Motor

- The DOF-5 includes stiff crossed roller bearings and brushless linear servo motor actuation, providing higher servo bandwidth and a better response for optical microscopy.

- The DOF-5 design is covered under U.S. Patent 10,367,436.

“Provides all the benefits of piezo in terms of speed and resolutions… with none of the limitations such as short travel range and ringing at a lower cost.”

Limitations of Piezoelectric Motors and Flexure Bearings

- Nanopositioning stages with piezoelectric motors and flexure bearings are expensive, have restricted travel, and stiffness issues.

- The DOF-5 Objective Focusing Stage has been engineered to overcome these performance drawbacks, offering greater travel (5 mm) and higher bandwidth (> 225 Hz) at a fraction of the cost.

- By embedding the servo drive and motion controller within the stage, we have removed complex cabling and reduced the overall system cost to typically 50-60% less than competing offerings, while still maintaining equivalent or better performance.

- The DOF-5 can also be connected directly to an Autofocus system for easy integration.

| wdt_ID | Piezo Flexure Stages | DOF Objective Focusing Stages |

|---|---|---|

| 1 | Typical piezo cost with controls ~$8,000 – $12,000. | Single nanopositioning system unit price with controls up to 50% less. |

| 2 | Flexure bearing results in off-axis motion and position dependent parasitic force. | Crossed roller bearing provides higher stiffness for faster moves. This results in increased throughput and longer nanopositioner life. |

| 3 | Stack or oscillating actuation have a non-linear response and bandwidth decreases as payload mass increases. | Brushless linear servo motor actuation provides higher servo bandwidth and a linear response for optical microscopy. |

| 4 | < 300 μm travel requires precise alignment and an additional coarse axis when more travel is required. | > 5 mm travel makes alignment easier. It also helps avoid microscope objective crashes and provides enough travel to clear interferences. |

| 5 | Oscillating piezos make a loud screeching noise. | A quiet servo is valued by lab workers. |

| 6 | Off-axis, complex controls are typically proprietary which leads to higher costs for piezo actuators. | Onboard controls result in a lower cost of ownership due to less complexity and fewer cables. |

What is “Nanopositioning”?

In the not-too-distant past, the precision tail-end of the bell curve in automation was often colloquially referred to as the “micropositioning” segment of the market. The term microposition derives from the fact that high-precision positioning systems were routinely operating at the micron level. Manufacturers in this space were specifying key system attributes such as Bi-directional repeatability, Accuracy, and Stability in units of microns. Such systems sufficiently filled industry demands from Life Science and Diagnostics, to Non-contact metrology, to the Tech sectors of Semiconductor, Data Storage, and Flat Panel Display.

Fast forward to our present day and no longer are such systems sufficient. Evolving industry needs in microscopy and biotechnology demand evolving levels of performance from precision positioning equipment manufacturers. As the features of interest across markets become smaller, the ability to position at the nanometer level becomes a market imperative. Dover Motion is proud to lead at the cutting edge of this new frontier of nanopositioning with groundbreaking products such as the revolutionary DOF-5 SmartStage™ Z axis focusing system and SmartStage Linear series single axis and XY systems.

This newest generation of products with repeatability, stability, and step-settle performance measured in nanometers more than addresses foreseeable industry needs. So, whether your cutting-edge instrument development is based on traditional diffraction-limited wide-field fluorescence microscopy; an increased resolution approach such as Confocal Laser Scanning Microscopy; or a super-resolution technique such as Structured Illumination Microscopy, Dover Motion’s aforementioned DOF-5 SmartStage Z axis stage is ready to provide all the objective nanopositioning performance required.

Advantages for Nanopositioning Microscopy

The use of a dedicated Z axis stage based on piezo actuators is currently the most commonly applied technique for high-performance and high-precision imaging; however, piezo-driven actuators have a number of very distinct limitations—despite their current dominance of the automated microscope focusing market.

The table below highlights the limitations of piezo stages and compares them with the features of our new DOF-5 objective focusing stage.

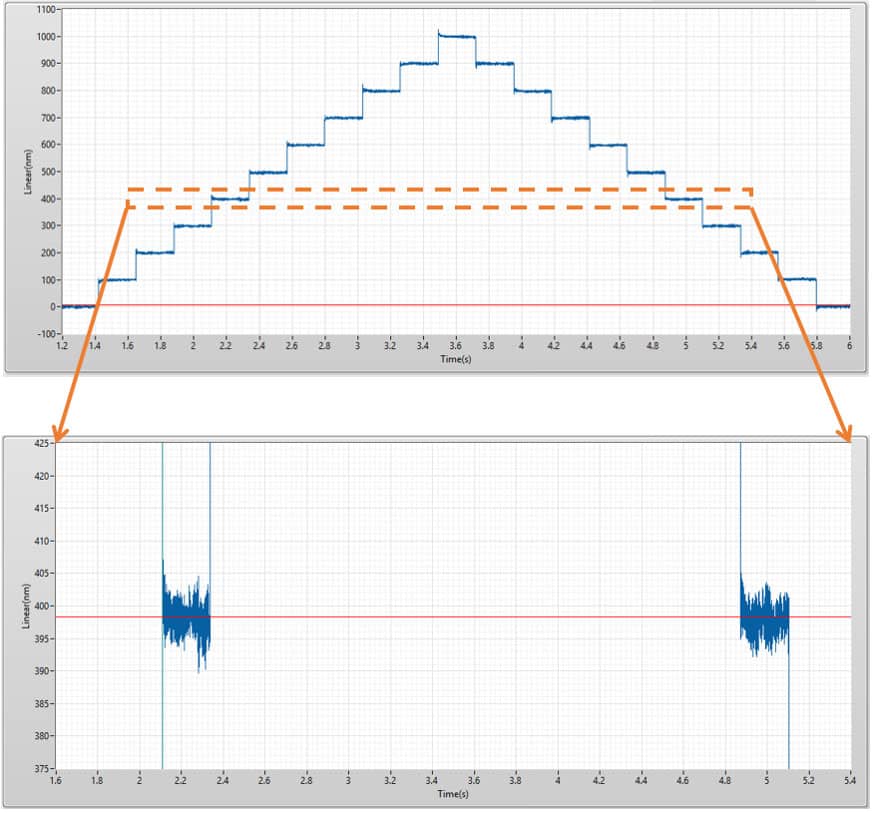

Performance Plots

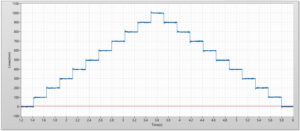

Fast, Accurate, and Repeatable 100 nm Moves

The above staircase plot displays position vs. time for ten consecutive 100 nm upward moves, followed by ten consecutive 100 nm downward moves. The data for the plot was taken at a 10-kHz sample rate, using a laser interferometer, and a plane mirror mounted at the base of a 300-gram objective. This staircase plot demonstrates the DOF-5’s ability to execute the very fast, accurate, and repeatable small moves typical in focusing applications.

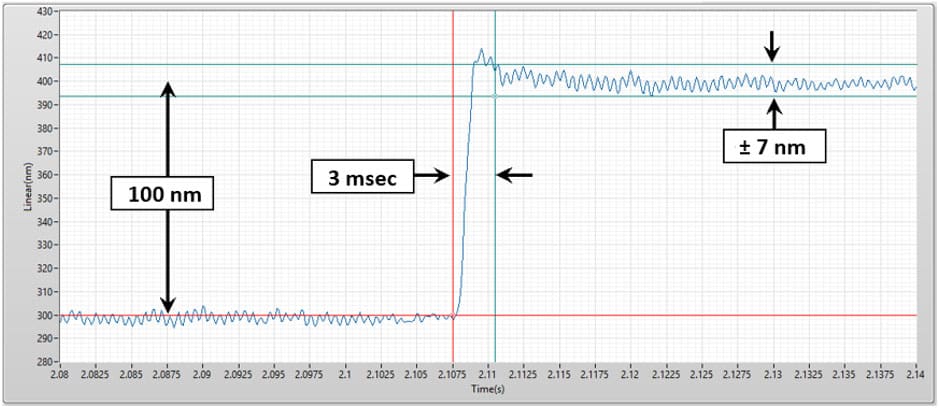

High Throughput Steps with Very Low Jitter

The above zoom-in on a single 100 nm step from the staircase plot demonstrates the high-throughput focusing capabilities of the DOF-5 Z axis stage. In the above move, with an initial position stability of < +/- 3 nm, the objective performs a 100 nm step, settling into and remaining within a ± 7 nm window, in under 3 msec.

Nanometer Level Bi-directional Repeatability

The above plot shows a zoom box being shown over a pair of positions within the 100 nm staircase move sequence. The two selected positions are nominally the same, but are being approached from opposing directions. The position on the left was made during upward moves, while the position on the right was made while moving downward. As such, any lack of bidirectional repeatability will show up when comparing these two positions.

In this extreme zoom, with a vertical scale of 5 nm per division, the two positions (nominally at 400 nm) are each visible at high resolution. Despite being 2.8 seconds apart, and approached from opposing directions, the difference between the mean of the two positions during their 250 msec position hold is under 2 nm.

Applications

The DOF-5 objective focusing stage was developed in response to the increasing throughput, resolution, and stability requirements of automated digital microscopy. Modern biomedical, life science and diagnostic instruments rely on automated digital microscope technologies. DNA sequencers, cell imaging instruments, and digital pathology scanners are just a few of the many applications for digital microscopy solutions. We have shipped thousands of objective focusing stages to support applications including:

- Next-generation sequencing (NGS)

- Digital cell morphology

- Automated digital pathology

- Optical metrology instruments

- Semiconductor and nanotechnology imaging

- Digital microscopes

- High content imaging

- Automated cell counting

Coordinated Motion

User defined profile mode (UDP) allows stages to coordinate motion using auxiliary inputs. Stages can be driven by another axis or external source to follow defined motion curves based off the input.

The DOF-5 is configurable for both vertical (Z-stage), and horizontal (x-stage) applications. Contact our applications engineers for more information.

Downloads

Datasheets

Whitepapers

Manuals

Software

Firmware

CAD Downloads

CAD Model

Request a Quote

"*" indicates required fields

* required fields

The information provided will be used in accordance with our privacy policy.