Specifications

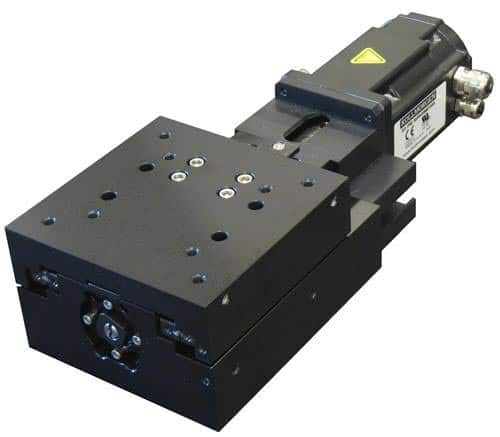

Ball Screw Linear Actuator – LMB™ Specifications

| wdt_ID | Base Model | LMB-200 | LMB-400 | LMB-600 | LMB-800 | LMB-1000 | LMB-1200 |

|---|---|---|---|---|---|---|---|

| 1 | Travel (mm) | 50 | 100 | 150 | 200 | 250 | 300 |

| 2 | Travel (in) | 2 | 4 | 6 | 8 | 10 | 12 |

| 3 | Accuracy (μm TIR) Linear Encoders | 8 | 10 | 15 | 20 | 25 | 30 |

| 4 | Accuracy (μm TIR) Open Loop | 13 | 15 | 20 | 25 | 30 | 35 |

| 5 | Bi-directional Repeatability (± μm) | 1 | 1 | 1 | 1 | 1 | 1 |

| 6 | Load Capacity (kg) | 75 | 95 | 125 | 145 | 175 | 175 |

| 7 | Flatness & Straightness (μm TIR) | 5 | 6 | 8 | 10 | 12 | 14 |

| 8 | Total Mass (kg) | 2.5 | 3.2 | 3.9 | 4.6 | 5.2 | 5.9 |

Description

The LMB™ series’ added precision ground preloaded ball screw provides benefits including running at higher speed than a lead screw, as well as providing significantly better repeatability performance due to less backlash in the nut. The added ball screw also increases axial stiffness, and its low friction provides more accurate and repeatable performance when combined with linear encoder feedback and closed loop servo control.

Duty cycle, life, and speed are also greatly improved with the ball screw actuator. The standard lead pitch is 2 millimeters and a larger thrust bearing is used to increase the axial load capabilities. These enhancements make this actuator ideal to be used in vertical applications. To prevent the stage from back driving, an optional inline stepper motor brake is available. A servo motor with built in brake is also available. The LMB™ series also has an added pinch cover design, eliminating any safety concerns. Travels are available from 2 to 10 inches.

Applications

The LMB™ ball screw linear actuator is best used for applications which require the higher level of repeatability that a ball screw provides, such as:

- Vertical large camera focusing

- Precise XY positioning of semiconductor wafers

- Backlash-free hardness testing

- Auto parts positioning for inspection

- Hard disk drive manufacturing equipment

Design Features

- Faster speed with ball screw

- More repeatable actuator positioning

- Best performance with closed loop control

Options

- Motor options available: stepper or servo motors

- Feedback options available: rotary encoder or linear encoder with analog or digital (1 um or 0.1 um resolution are standard, other resolutions available upon request)

- Download the datasheet for additional technical details

Downloads

Datasheets

CAD Downloads

CAD Model

Request a Quote

"*" indicates required fields

* required fields

The information provided will be used in accordance with our privacy policy.