Wafer Inspection, Scanning, and Probing Applications

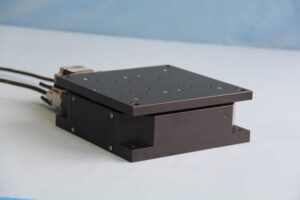

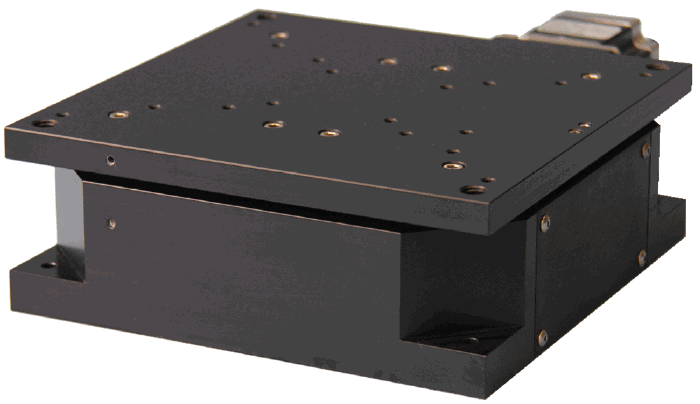

Dover Motion’s precision vertical stage – ZE™, provides a very compact, accurate means of achieving vertical motion. Designed to satisfy the high demands of wafer inspection, scanning, and probing applications, this vertical lift stage delivers exceptionally straight, smooth, and repeatable motion. Multiple travel options are available from 0.5 up to 1.5 inches in a low profile design.

Specifications

Precision Vertical Stage – ZE™ Specifications

| wdt_ID | Base Model | ZE-05 | ZE-10 | ZE-15 |

|---|---|---|---|---|

| 1 | Travel (mm) | 12.5 | 25 | 38 |

| 2 | Travel (in) | 0.5 | 1 | 1.5 |

| 3 |

Positional Accuracy (±μm)*1 |

38 | 76 | 114 |

| 4 | Bi-directional Repeatability (± μm) | 1.5 | 1.5 | 1.5 |

| 5 |

Load Capacity (for all, kg)*2 |

12.5 | 12.5 | 12.5 |

| 6 | Flatness & Straightness (μm TIR) | 5 | 10 | 15 |

| 7 | Total Mass (kg) | 7.4 | 9.1 | 13.1 |

*1 Stepper motor; open loop. Accuracy improves with encoder feedback or compensation.

*2 Please contact our Applications Engineers for loads exceeding the specification.

Description

In the Dover ZE™ stage, precision, non-recirculating ways in each of the four corners keep pitch and yaw below 15 arc-seconds over full travel. Both 0.5-inch and 1-inch travel versions are available with collapsed heights to minimize the size of this precision vertical stage. The 8-inch square mount plate allows the load to be placed in line with the lift force and eliminates the need to cantilever the payload.

Our precision vertical stage incorporates a NEMA 23-frame motor (either stepper or servo) coupled to a lead screw which drives a cam-follower along a wedge. This design provides high resolution while our anti-backlash friction nut ensures excellent repeatability. Each stage includes precision Hall effect limit switches which terminate on convenient, locking D sub-mini connectors. The pitch of the lead screw, the ratio of the wedge mechanism, the motor, and the controller together determine the resolution in our ZE™ stage.

Design Features

- Low profile with no cantilevering

- Excellent straightness and repeatability

- Anti-backlash friction nut

Options

- Motor options available: stepper or servo

- Feedback options available: rotary encoder

- Download the datasheet for additional technical details about this motorized z axis stage

- View all of Dover Motion’s Z stages

Applications

Our ZE™ stage is popular for wafer inspection, scanning, and probing applications.

Downloads

Datasheets

CAD Downloads

CAD Model

Request a Quote

"*" indicates required fields

* required fields

The information provided will be used in accordance with our privacy policy.