Abbé Error

Abbé error (pronounced ab-¯a) can be a significant source of error in positioning applications

Named after Ernst Abbé, a noted optical designer, it refers to a linear error caused by the combination of an underlying angular error (typically in the ways which define the motion) and a dimensional offset between the object being measured and the accuracy determining element (typically a leadscrew or encoder). In open loop systems (or closed loop systems employing rotary feedback), the accuracy is nominally determined by the precision of the leadscrew. Similarly, in systems with linear encoders or interferometers, it is that device which determines the accuracy. It is important, however, to recall exactly what information these devices provide: Leadscrews really tell us nothing but the relative position of the nut and screw, and encoders tell us only the position of the read head relative to the glass scale. Extrapolating this to include the position of an item of interest, despite its firm mechanical connection to the nut or encoder read-head, is ill founded.

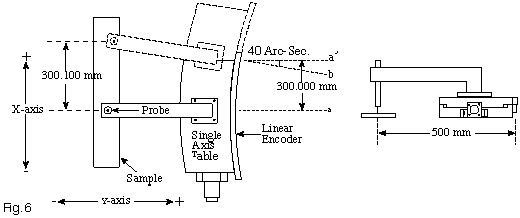

To illustrate this, consider Figure 6, which shows a single-axis stage with a linear encoder. The stage carries an offset arm which positions a probe over a sample. The apparent distortion in the stage is intentional; it is intended to illustrate, in exaggerated fashion, a stage whose ways have a curvature (in this case, yaw). Someone using this stage, and in possession of appropriate test instruments, would measure an error between the stage position as determined by the encoder read-head, and the actual linear position of the probe.