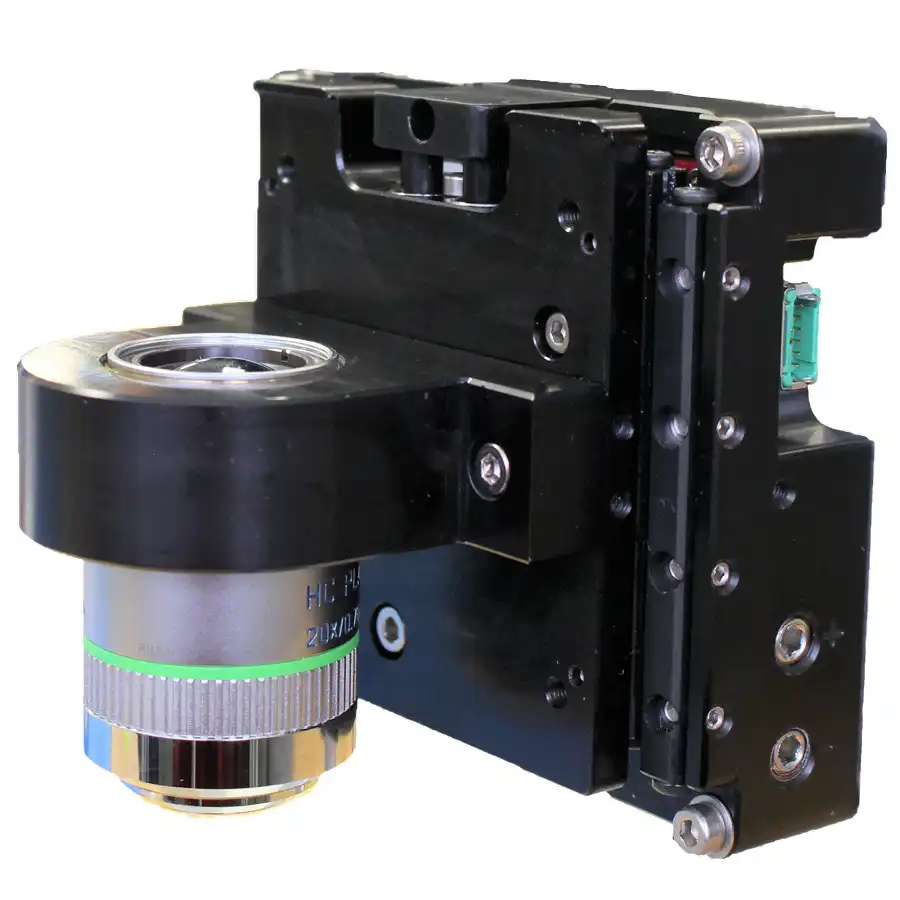

SmartStage™ Linear Positioning Stage

The SmartStage™ linear positioning stage, available as SmartStage™ Linear for single axis or as SmartStage™ XY for dual axis, comes in a range of travel sizes and options to meet your precision motion needs.

Benefits of a SmartStage™ XY

-

ALL controls inside; ONE external cable

-

5 nm resolution

-

0.8 um bi-directional repeatability

-

Easy for prototyping

-

Cost-effective for production

Specifications

SmartStage™ XY Linear Positioning Stage Specifications

*Recommended for TDI Scanning Applications

** Other resolutions available, for options contact an applications engineer

*1 Accuracy has 2 point slope correction applied

*2 Please contact our Applications Engineers for loads exceeding 10kg.

*3 The maximum acceleration and velocity is resolution and load dependent.

*4 Linear stage must be mounted to a flat surface, see datasheet for details

Description

SmartStage™ positioning stages offer the following features and benefits:

Hardware Agility:

- Unique, compact, integrated motion stage and miniaturized controller, with a single combined power and communications cable.

- Easy integration; with minimized footprint, complexity, and lower parts count inside your instrument.

- Integrated solution for multiple stages.

Performance:

- Precise, high-performance motion control – and supporting software tools – for the most demanding applications.

- Compelling price-to-performance ratio, achieved using an innovative and patented system architecture.

- US Patent 10,374,530

- US Patent 10,367,436

- Long-life: quiet brushless linear motor, non-contact encoder, crossed-roller linear bearings.

Dependability:

- Reliability and confidence of an experienced supplier.

- More than 22,000 motion systems shipped to Fortune 500 companies worldwide.

- On-time delivery of over 95%.

Integrated Solution:

- By including the encoder, interpolator, drive, and motion controller electronics all within the stage, the SmartStage positioner is able to achieve high in-position stability and avoid noise errors introduced by external cabling, poor grounding, and other detrimental influences on the feedback signal.

- Ecosystem of SmartStage XY and DOF-5 objective focusing stage provides an integrated control solution for your applications.

- Simplify software architecture with common API between X,Y, and Z stages.

Precision Linear Motor:

- The novel magnetic topology of Dover Motion’s ironless linear motor technology is optimized for high servo bandwidth and uniform force over the entire stroke, and it has no backlash as commonly experienced with screw-based positioners. This allows the SmartStage XY axes to perform equally well for applications requiring high-throughput step and settle or constant velocity scanning.

Step-settle test results: 20 (10 in each direction) moves of 400um settling to +/-25 nm within 36ms

The test was performed 3 times starting at 0mm, 25mm, and 45mm on the upper axis of an SS-XY-50×50 w/ 1.25nm resolution encoder and a 200g payload.

Optional SmartStage XY Ultra Resolution Encoder:

- Provides ultra low encoder sub-divisional error resulting in +/- 5nm position accuracy per 100 um of travel. This is especially useful when used with Trigger On Position for accurate camera or laser triggers while scanning.

All while providing high performance

- A potent combination of crossed roller bearing ways and Dover Motion’s linear motor drive system results in superior instrument performance.

- Stiff, crossed roller bearings allow for a wide range of payloads. These bearings also offer exceptional trajectory performance and excel for applications such as constant velocity scanning that requires smooth motion.

- Smooth and Stable Motion: The unique motor design combined with ultra-precision encoder provides consistent force over the entire travel of the stage resulting in extremely low velocity ripple while scanning and < 30nm stability at rest.

- High Resolution Trigger On Position for Image Capture or Laser Synchronization: High speed hardware output with < 1 nm resolution for synchronizing stage position with a camera or laser. Ideal for triggering during motion commonly required for TDI Imaging or laser processing.

Table 1: The SmartStage XY is smaller, lighter, and has fewer cables

| wdt_ID | Dover Motion SmartStage XY | Traditional Linear Motor Stage | Traditional Leadscrew Stage | |

|---|---|---|---|---|

| 1 | XY Travel (mm) | 100 x 100 mm | 100 x 100 mm | 100 x 100 mm |

| 2 | Volume Including Controls (cm3) | 1,477 | 2x Larger | 4x Larger |

| 3 | Weight (kg) | 2.2 | 40% Heavier | 30% Heavier |

| 4 | Cable Count (# of cables for XY stack) | 1 | 4 | 4 |

Applications

The SmartStage™ XY series of linear positioning stages for single axis or stacked XY linear motion was developed in response to the increasing throughput, resolution, and stability requirements of automated microscopy. SmartStage™ XY is the ideal choice for precision positioning applications when accurately positioning your sample, such as a microscope slide or a flow cell. We have shipped thousands of positioning stages to support applications including:

- Next-generation sequencing (NGS)

- Digital cell morphology

- Automated digital pathology

- Optical metrology instruments

- Semiconductor and nanotechnology imaging

- Digital microscopes

- High content imaging

- Automated cell counting

High Resolution Trigger On Position for Image Capture or Laser Synchronization

- High speed hardware output with < 1 nm resolution for synchronizing stage position with a camera or laser. Ideal for triggering during motion commonly required for TDI Imaging or laser processing

- A high-speed Trigger On Position output allows precise synchronization of a camera, laser, or other peripheral device with the exact position of the stage. Triggering is configurable at either fixed incremental intervals, or at arbitrary intervals using a user-defined look up table.

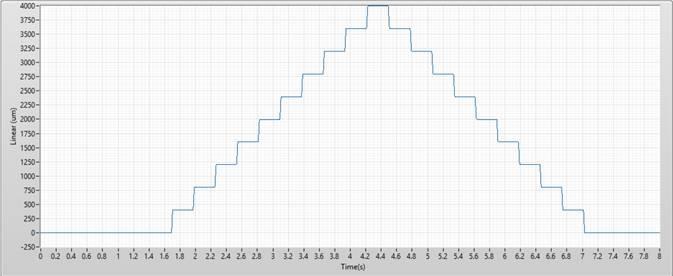

Coordinated Motion

- User defined profile mode (UDP) allows stages to coordinate motion using auxiliary inputs. Stages can be driven by another axis or external source to follow defined motion curves based off the input.

Downloads

Datasheets

Whitepapers

Manuals

Software

Firmware

CAD Downloads

CAD Model

Request a Quote

"*" indicates required fields

* required fields

The information provided will be used in accordance with our privacy policy.