Tip Tilt Stage

A tip tilt stage is a mechanical device used in various applications to precisely control the angular position of an object or component. It allows for fine adjustments in both the tilt and tip directions to enable precise alignment and positioning.

Dover Motion offers tip tilt stages that are customized for your unique applications and integrated within the structure of another stage assembly or the sample holder assembly.

Typical tip tilt stages for microscopy applications offer just a few degrees of rotation. This compensates for minor variations that would make a sample play imaging plane outside of the desired depth of field for the optical assembly, which is usually needed for applications with a high numerical aperture or high magnification objective.

Tip Tilt Stage Guide

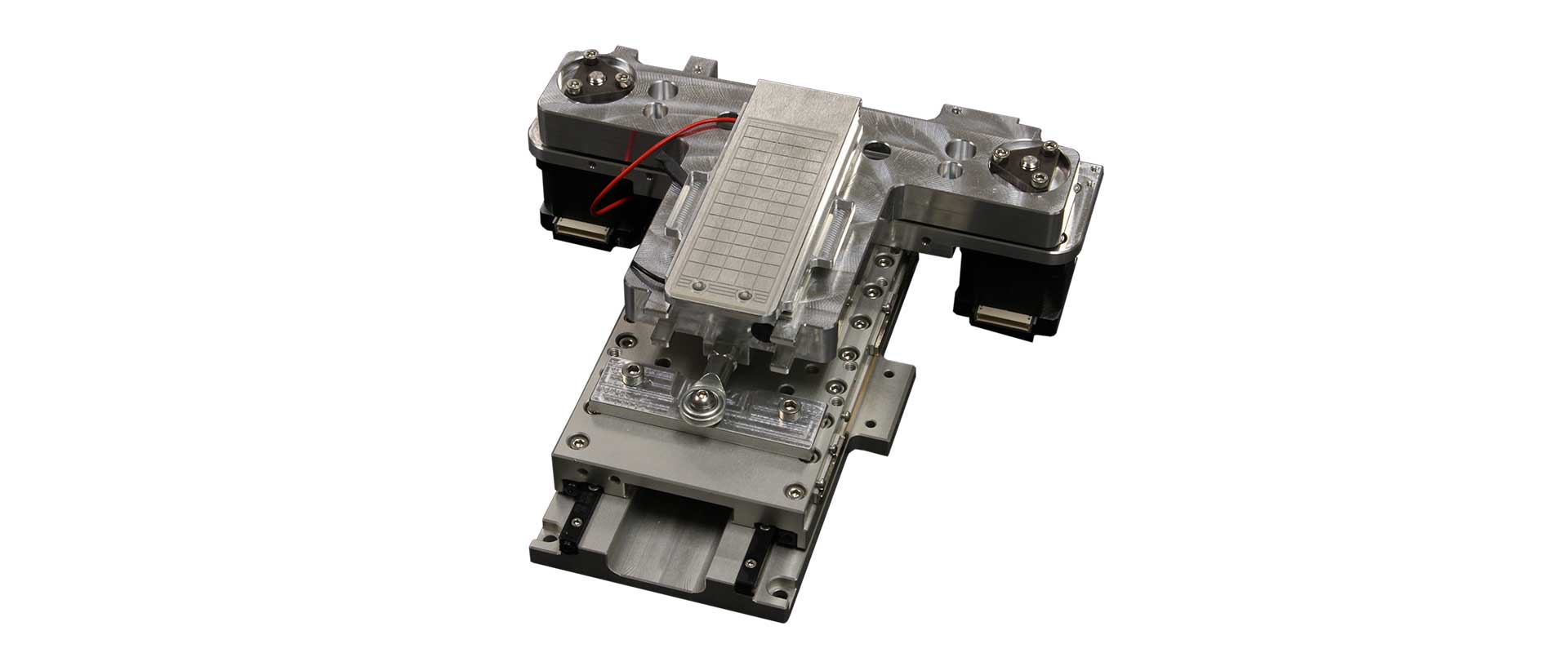

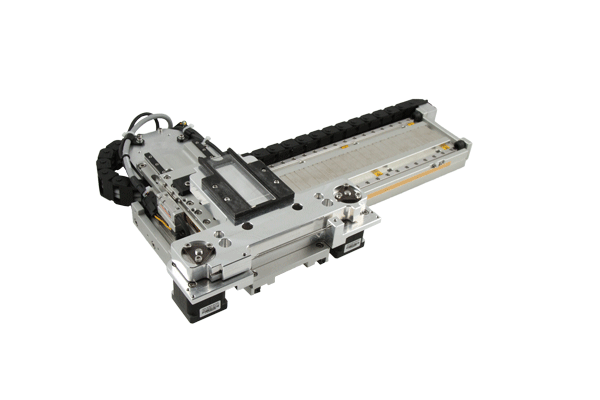

In the example below, we will review the tip tilt stage structure and discuss its components. Item #4 on the picture is the slide holder/sample holder. Items #1 and #2 are the tip-tilt actuators, and item #3 shows the pivot point for the rotation. Moving only actuator #1 or actuator #2 would provide a tilt or roll of the sample. Moving both actuators #1 and #2 together would provide a tip or pitch of the sample with respect to the pivot point. A tip tilt mechanism is typically mounted on top of additional axes, usually an XY stage as shown in the example in item #5.

1

1Tip-Tilt Actuator #1

2

2Tip-Tilt Actuator #2

3

3Pivot Point

4

4Slide Holder/Sample Holder

5

5Y Stage

Tip Tilt Stage Benefits

The benefit of a tip till stage is to ensure that clear images are captured by keeping the imaging area of interest within the focal plane/depth of field. This is useful when the sample is placed on a surface that isn't perfectly flat, such as a glass slide, microfluidic, or well plate. Using tip tilt to adjust the sample angle at different imaging locations can compensate for flatness or parallelism variations inherent to the sample carrier or the motion stage(s), which is positioning the sample.

Typical use cases for a tip tilt stage

Tip-tilt stages find applications in a wide range of industries and fields, including:

- Optics and Photonics: In the field of optics and photonics, tip-tilts are used for aligning and stabilizing optical components such as mirrors, lenses, prisms, and beam splitters. They help in achieving accurate beam steering, collimation, and focusing, which are crucial in applications like laser beam control, imaging systems, and optical communication.

- Astronomy and Telescopes: Tip tilt stages are used in astronomical telescopes to compensate for atmospheric turbulence and vibrations. By continuously adjusting the position of the telescope's primary mirror or secondary mirror, these stages help in maintaining a stable and clear image of celestial objects, even under challenging atmospheric conditions.

- Microscopy: In microscopy, tip tilt stages are employed to precisely align and position a sample with respect to a microscope objectives, allowing for accurate focusing and imaging. They are particularly useful in applications such as confocal microscopy, where precise control over the focal plane is essential for obtaining high-resolution images.

- Semiconductor Manufacturing: Tip tilts are used in semiconductor manufacturing processes for aligning and positioning wafers, masks, and other critical components. They play a crucial role in ensuring precise alignment during lithography, wafer inspection, and other fabrication steps, contributing to the production of high-quality semiconductor devices.

- Precision Engineering: Tip tilt stages are utilized in precision engineering applications, such as alignment and positioning of optical systems, laser machining, microfabrication, and nanotechnology. They enable accurate control over the orientation and position of components, ensuring precise and repeatable results.

Overall, tip tilt stages are essential tools in various industries where precise angular positioning and alignment are required. They contribute to improved performance, accuracy, and stability in a wide range of applications, ultimately enhancing the quality and efficiency of processes and systems.

How is a tip tilt stage used with rotary motion?

When using a tip tilt in conjunction with rotary motion, the aim is to achieve both angular adjustments and rotational movement. This combination allows for even greater flexibility and control in positioning objects with complex angular requirements.

By integrating a tip tilt stage with a rotary stage, it becomes possible to achieve precise angular adjustments in multiple directions while also rotating the object around a fixed axis. This can be particularly useful in applications where both angular alignment and rotational movement are critical, such as aligning optical components or directing laser beams.

The integration of tip tilts with rotary motion enables the precise manipulation of objects in three-dimensional space, providing enhanced control and accuracy in various scientific, industrial, and research applications.

Can a tip tilt stage be integrated with other motion control systems?

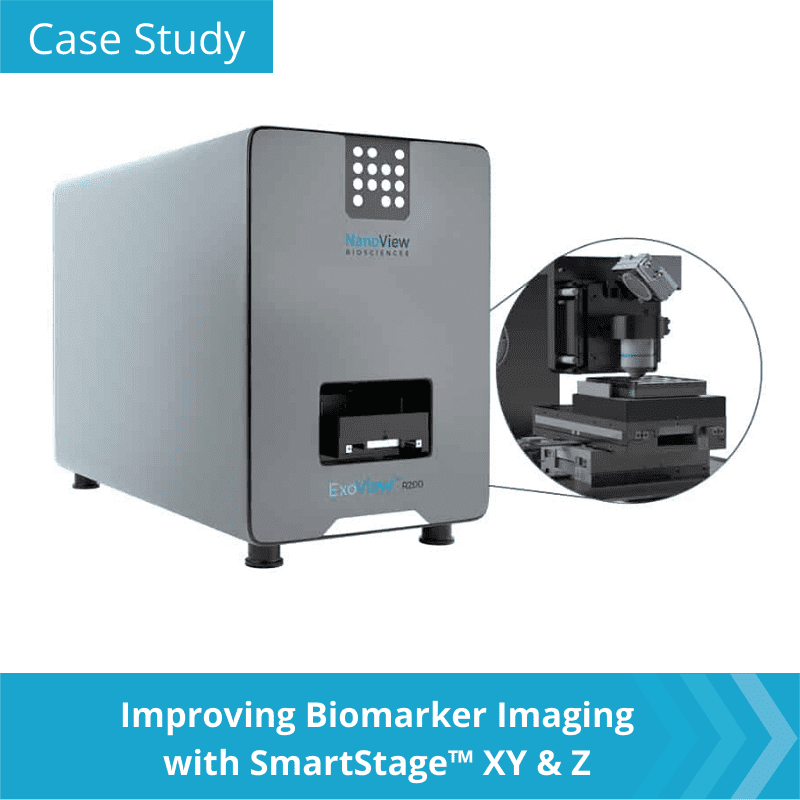

Yes. Tip tilt stages can be integrated with other motion control systems. In the example on the right, the tip tilt is mounted to a precision crossed roller Y axis and a long travel shuttle-style X axis that allows for easy sample loading and unloading.

Are tip tilt stages suitable for high-precision applications?

Tip tilt stages are usually used for microscopy and high precision applications where there is a very small depth of field and a large sample, bigger than the field of view.

These types of stages ensure the area of interest stays within focus across a two-dimensional XY scanning area. They compensate for the flatness and parallelism of the XY sample positioning stages as well as flatness and parallelism variations in the sample holder such that the plane of focus is maintained across the entirety of the sample.

Custom Design Capabilities

Dover Motion has experience developing tip-tilt stages that will meet application needs and fit within the allocated footprint to minimize the overall size of the motion control system. Below, you can find the tip tilt stage designed for moving larger samples positioned on top of Dover Motion’s standard SmartStage™ XY.