Precision Motion Stages for Additive Manufacturing

Solving Critical Motion Challenges in Additive Manufacturing

Dover Motion’s precision motion systems are engineered to meet the unique demands of additive manufacturing—combining sub-micron accuracy, high speed throughput, and seamless integration with complex print systems. Our customizable XY, Z, and multi-axis stages deliver precise motion control for reliable deposition and sintering, backed by fast prototyping and engineering support to streamline your development process.

From Standard to Custom

Dover Motion offers standard and custom motion solutions designed to meet the demands of additive manufacturing, including:

- High speed motion for faster build cycles

- Highly responsive motion for accurate, real-time control

- Precision positioning for reliable material deposition and fine-feature detail

Recommended Products:

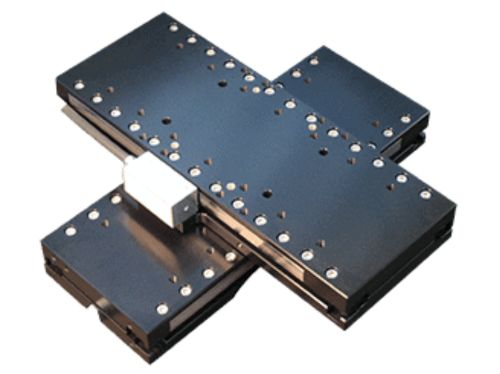

SmartStage™ XY Monolithic Stage

The SmartStage XY Monolithic stage, is a linear motor stage in a low-profile XY form factor, with physically integrated controller, designed for precision positioning.

| wdt_ID | Travel | 50 - 75 mm |

|---|---|---|

| 1 | Accuracy | 12 μm |

| 2 | Repeatability | 0.8 μm |

| 3 | Payload (kg) | 10 kg |

SmartStage™ XY

The SmartStage™ XY linear positioning stage, also available as a single axis, offers high precision and includes an embedded controller inside the stage.

| wdt_ID | Travel | 50 - 200 mm |

|---|---|---|

| 1 | Accuracy | ≤ 10 μm |

| 2 | Repeatability | 0.8 μm |

| 3 | Payload | 10 kg |

SmartStage™ Z-50

The SmartStage™ Z-50 provides a unique combination of travel distance and precision for vertical Z axis stage applications.

| wdt_ID | Travel | 50 mm |

|---|---|---|

| 1 | Resolution | 5 nm |

| 2 | Accuracy | 10 μm |

| 3 | Repeatability | .8 μm |

SmartStage™ Shuttle Long Travel Stage

The SmartStage Shuttle is a long travel linear stage, which provides linear motor precision and throughput for XY stage applications.

| wdt_ID | Travel | 200 - 500 mm |

|---|---|---|

| 1 | Accuracy | 5 μm |

| 2 | Repeatability | 1.2 μm |

| 3 | Payload | 10 kg |

KV™

The KV™ micro linear stage is a lead-screw-driven step motor stage with a miniature size.

| wdt_ID | Travel | 25 - 200 mm |

|---|---|---|

| 1 | Accuracy | 15 μm TIR |

| 2 | Repeatability | < ± 3 μm |

| 3 | Payload | 15 kg |

Why Choose Dover Motion?

Unmatched precision: Our motion systems are engineered for sub-micron and nanometer-level accuracy—ensuring consistent, high resolution layer deposition for even the most demanding additive manufacturing applications.

Customizable Solutions: We collaborate closely with OEMs to develop custom XY, Z, and multi-axis motion stages that match the unique requirements of your additive manufacturing processes.

Robust & Reliable: Designed for continuous operation in challenging production environments, our systems deliver long-term stability, even under high thermal and mechanical stress.

Advanced Motion Control: Powered by our Motion Synergy™ API, our systems enable precise motion profiles, high-speed triggering, and advanced synchronization—ideal for executing complex toolpaths, managing overhangs, and controlling dynamic deposition processes in additive manufacturing.

Scalable from Prototype to Production: Whether you're building a benchtop system or scaling to full production lines, our motion platforms are designed to grow with your application—supporting both rapid iteration and volume manufacturing.

Additional High Precision Motion Resources

Contact Us

Request a Demo Short

"*" indicates required fields