The Ultimate in Performance, Reliability, and Value

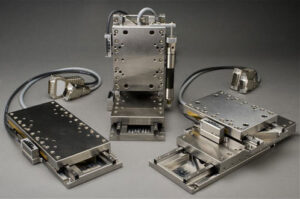

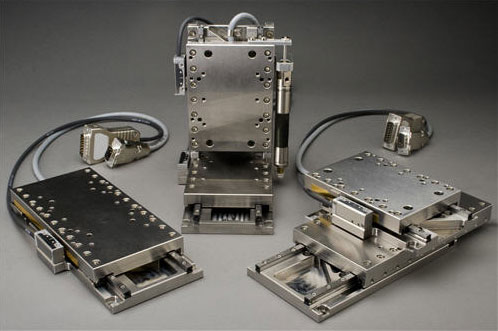

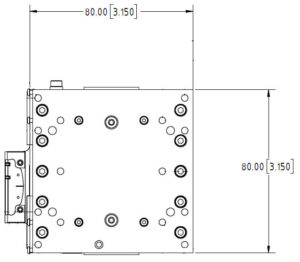

Miniature linear stage is a compact direct drive stage with an actuator specifically designed to fit inside benchtop instruments and small spaces. At Dover Motion, we offer the ultimate solution for miniature linear stages – the Miniature Linear Stage – MMX™. The MMX™ stage delivers exceptional mechanical stiffness and servo bandwidth, making it the perfect fit for high throughput imaging applications.

Specifications

Miniature Linear Stage – MMX™ Specifications

| wdt_ID | Base Model | MMX-25 | MMX-50 | MMX-100 | MMX-150 |

|---|---|---|---|---|---|

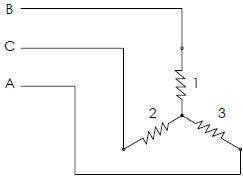

| 1 | Motor Type | 1 Phase | 3 Phase | 3 Phase | 3 Phase |

| 2 | Travel (mm) | 25 | 50 | 100 | 150 |

| 3 | Accuracy (μm TIR) | 6 | 10 | 12 | 12 |

| 4 | Bi-directional Repeatability (± μm) | 0.4 | 0.4 | 0.4 | 0.4 |

| 5 | Load Capacity (kg) | 10 | 10 | 10 | 10 |

| 6 | Maximum Acceleration (m/s2) | 55 | 115 | 100 | 65 |

| 7 | Maximum Velocity (m/s) | 1.1 | 2.0 | 2.0 | 2.0 |

| 8 | Flatness & Straightness (μm TIR) | 3 | 3 | 6 | 6 |

| 9 | Motor Peak Force (N) | 23 | 57 | 57 | 57 |

| 10 | Motor Continuous Force (N) | 7.7 | 19 | 19 | 19 |

| 11 | Moving Mass (kg) | 0.4 | 0.5 | 0.6 | 0.9 |

Description

The new MMX™ high power motor has a higher force density to deliver 5 times the force of similar products from other companies. Our miniature linear stage is also available with 3 phase servo motors in travels from 25 to 150 millimeters. The MMX™ stage delivers nearly twice the accuracy at virtually the same cost as competitive standard-grade options. It provides short lead times, reducing time to market for equipment manufacturers and providing greater machine uptime for end users.

MMX™ Miniature Linear Stage Design Features

- Unique motor design provides the compact linear actuator smoother motion with industry leading velocity stability

The brushless and ironless linear servo motor inside our miniature linear stage allows for high speeds with no maintenance, making it ideal for use in high throughput applications. Furthermore, it delivers cog free smooth motion coupled with an impressive 6 μm TIR accuracy and a 0.4 ± μm repeatability (MMX-25 configuration).

- Smallest package size using direct drive linear motor technology in a 1-inch travel positioner

Direct drive linear motor technology utilizes a direct power transfer mechanism and, in most cases, is a better alternative to a traditional mechanical transmission system, delivering valuable benefits to its users. These benefits include enhanced precision, reduced wear, faster response times, and quieter operation for seamless integration.

- Lower cycle times with the most powerful servo motor design in a small form factor

Our unique motor design allows for higher throughput. The motor in the high power MMX stage has a higher force density to deliver 5 times the force of similar competitive products with a peak force reaching 57 N in a 3 phase motor.

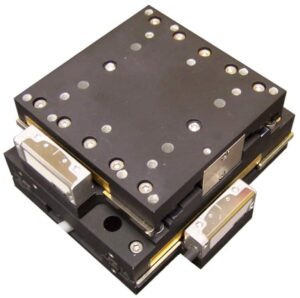

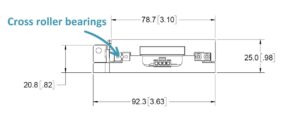

- Increased throughput with fast settling due to stiff cross roller bearings and a powerful motor

MMX linear stages use high precision anti-creep crossed roller bearings for extremely smooth motion, high stiffness, and reliability in a low profile package. This allows for higher throughput without increasing the overall height.

- Customizable and stackable design ensures fit within unique applications

Our miniature linear stages can be combined into multi-axis assemblies, including Z configurations with an integral constant force magnetic counterbalance. Therefore, applications such as objective focusing, probing, laser machining, and force measurement will benefit from its customizable and stackable design.

- Best-in-class accuracy from high-resolution encoder feedback and servo control

Depending on specification, our miniature linear stage- MMX delivers 6-12 μm TIR accuracy. Additionally, it is equipped with an adjustable mount for externally adjustable limit sensors.

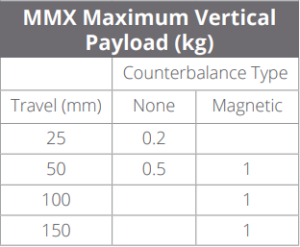

- Highest load capacity of 500 grams without a counterbalance

Our 1-phase MMX-25 stage can handle 0.2kg payload. The 3-phase MMX-50 utilized a magnetic counterbalance to increase the payload to 1 kg.

Options

- Motor options available: ironless direct drive servo motors

- Feedback options available: linear encoder with analog or digital (1 or 0.1-micron resolution are standard, other resolutions available upon request)

Applications

For high throughput imaging applications, the MMX™ direct drive stages deliver excellent mechanical and servo stiffness to optimize motion for:

- Sample/part positioning: sustained throughput of up to 2000 moves per minute are possible

- Focal plane definition: Z objective positioning moves (less than 5 microns) are often accomplished in less than 20 milliseconds, in parallel with XY stepping

- Frame capture: in-position stability is key to producing quality images; position stability/jitter is typically less than 100 nanometers

- Space savings: compact linear actuator designed to fit inside benchtop instruments

Downloads

Datasheets

CAD Downloads

CAD Model

Request a Quote

"*" indicates required fields

* required fields

The information provided will be used in accordance with our privacy policy.