Specifications

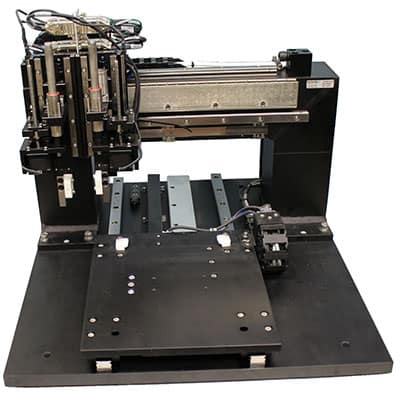

XY Gantry System – SAX Specifications

| wdt_ID | Base Model | Y Axis (Upper) | X Axis (Lower) |

|---|---|---|---|

| 1 | Travel (mm) | 290 | 270 |

| 2 | Accuracy (μm) | 10 | 10 |

| 3 | Bi-directional Repeatability (± μm) | 1 | 1 |

| 4 | Flatness (μm) | 10 | 10 |

| 5 | Straightness (μm) | 10 | 10 |

| 6 | Pitch (arc-seconds) | 50 | 50 |

| 7 | Yaw (arc-seconds) | 50 | 10 |

| 8 | Orthogonality (arc-seconds) | 20 | 20 |

Description

The non-contact, cog-free linear motors of the SAX gantry system are ideally suited for pick-and-place, 3-D printing, step and settle, as well as scanning applications. They produce quiet motion with low velocity ripple. Non-contact absolute encoders are standard for the SAX. They combine precision position feedback with instant position on power-up, so there is no need for homing routines.

Encoders are positioned close to the customer’s point of interest to reduce Abbe errors. More traditional incremental feedback is an option as well. Utilizing lightweight aluminum construction, the SAX combines high-accuracy and sub-micron repeatability, with angular errors less than 50 arc-seconds. Standard mounting hole configurations allow for mounting other Dover stages such as the RTR rotary table on the lower carriage and KV and MMX miniature linear stages on the upper carriage.

Design Features

- High accuracy and repeatability with optimized encoder locations

- High speed and acceleration with ironless, cog-free motors

- Low audible noise

- Configurable and Customizable

- High flex cable

Options

- Custom XY and Z travel lengths

- Incremental or absolute linear encoders

- Mounting hole configurations allow for mounting other

- Dover stages, such as the RTR rotary stage on the lower carriage, and KV and MMX stages on the upper carriages

Applications

The split-axis gantry is ideal for high-accuracy and high-duty cycle applications. A few ideal applications are:

- Imaging

- Automated part inspections

- 3-D printing

- Material dispensing

- Metrology

Downloads

Datasheets

Request a Quote

"*" indicates required fields

* required fields

The information provided will be used in accordance with our privacy policy.