Dover Motion’s Direct Drive Technology for Cell Imaging Exceeds Piezo Stage Performance with Lower Cost

At a Glance

- A client was developing a digital cytology instrument for cancer screening

- Their prototypes, based on proprietary ultrasonic standing wave piezoelectric motors, had been unable to focus at the resolution required and were pushing the client beyond their cost and timeline targets

- We collaborated to create an XY stage and a Z stage that met performance requirements at one third the cost and got the client back on track with their timeline and budget

- The instrument received FDA approval and captured >70% of the target diagnostic test market with throughput 3x the previous benchmark

Piezo Stage Issues

A company was developing an automated digital cytology instrument for cancer screening. To actuate their slide positioning and objective focusing stage prototypes, they selected a popular modular motor incorporating a proprietary ultrasonic standing wave piezoelectric technology. However, they were unaware of the inherent technical limitations of their technology choice. These included temporal sensitivity to servo tuning, significant component wear, unreliability due to fragility, and particulate generation due to the highly-preloaded, ceramic motor-on-ceramic spar architecture. Additionally, this design approach resulted in a large friction dead band and the poor control stability inherent in such systems. It could not deliver the ultra-high precision required to focus at the cellular level and repeatably position the sample. Because of this, the prototypes had been unable to meet their cost or performance requirements needed to replace the slow, error-prone process of having a pathologist manually analyze each slide.

The company was falling behind schedule and desperate when they came to Dover Motion for a solution. To learn more about the limitations of piezo stages, we have an educational video and detailed transcript here.

Direct Drive Stages, A Better Alternative

Dover Motion worked with the client’s development team to meet their design goals with a customized direct drive linear motor XY and Z stage.

The client required:

- A stiff precision XY linear stage to position the slides

- A motorized Z focusing stage with built in objective for clear cell imaging

- The XY translation stage and Z axis fast enough to make 20 stable site measurements per second

- The compressed schedule required the novel positioning system be developed in parallel with the diagnostics instrument to keep the project on time

- The positioning system had to meet aggressive cost targets, and be shipped as a fully tested and pre-aligned drop in modular assembly

Low Cost Solution

In a concurrent and collaborative effort, Dover Motion quickly designed a compact, custom XYZ stage solution to enable high-precision cell imaging.

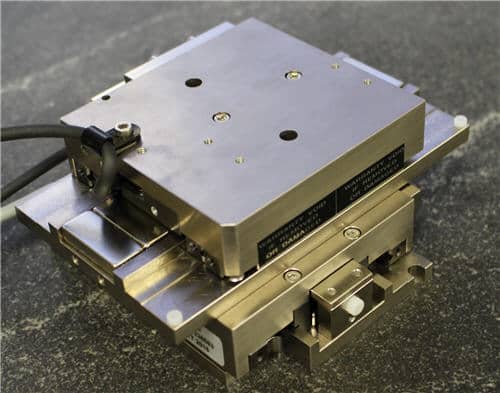

We designed a small, high-precision direct drive XY translation stage to position the slide. It has stiff crossed roller guide ways for high stability, and direct drive linear motors with encoder feedback for high speed, accuracy, and repeatability. This XY stage provides high throughput slide site to site motion.

For focusing the Z axis, a unique low-cost and high-precision approach is used. The objective lens is mounted directly into a flexure rod-based motion assembly which eliminates the need for the client to perform any optical alignment saving integration time on each instrument manufactured.

The flexure rod assembly does not require the precision machining of a conventional mechanical stage, and it has greater precision. Each of these features greatly reduces the cost and complexity of the Z axis.

The XY stage and the Z axis motion assemblies are mounted within a rigid, co-developed, cast metal frame that integrates directly into the instrument structure. Dover Motion fully tests and servo tunes the imager axes, so there is no additional customer functional testing or time consuming optical alignment needed.

A Market Leading Solution

Dover Motion worked closely with the client in order to:

- Engineer their motion system in parallel with their instrument development

- Keep the project on its cost and schedule targets

- Quickly deliver a positioning system that has better cell imaging positioning performance at a third the cost of the competing piezo stage technology

- Confirm the instrument’s necessary high throughput and precision rates, processing 20 stable images a second while accurately moving 384 microns between sites

No longer needing a pathologist to manually analyze each slide, the new cancer screening instrument automatically examines hundreds of slides and selects the appropriate ones for human review. This results in a >50% increase in lab productivity and more accurate clinical diagnoses. The new instrument quickly received FDA approval and has captured >70% of the specific diagnostic test market.

This Dover Motion direct drive XY translation stage positioning technology is also being used in other diagnostics imaging instruments due to its compact size and accurate positioning. For more information on our XY and Z products click on the links: