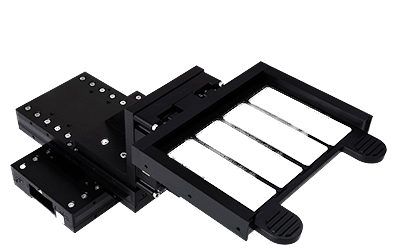

Translation Stage

A translation stage, also called a linear translation stage, is a high-precision mechanical device designed to move objects in a linear direction along one or more axes. It ensures accurate positioning and smooth movement of the object, making it essential for tasks requiring precise control in life sciences, automation, manufacturing industries, microscopy, optical alignment, and scientific research applications.

Below is a catalog of Dover Motion’s translation stages that include direct drive linear motor and screw driven translation stages. Our stages are optimized for various uses, such as precision motion, high speed, and compact size, and can be customized to meet your specific needs.

Translation Stage Types

Our Key Advantage

- Precision:

One of the key advantages of Dover Motion’s linear translation stages is their precision. Our stages are designed to provide ultra-smooth and accurate movement, even in applications that require nanometer-level precision. This level of accuracy is essential for industries such as microscopy and semiconductor manufacturing, where even the slightest deviation can lead to major errors or defects. - Durability:

Another advantage of Dover Motion’s stages is their durability. Our stages are built to withstand even the most demanding applications up to 100,000km, with rugged construction and high-quality materials that ensure long-lasting performance. Whether you're using your stage in a laboratory setting or an industrial environment, it will provide reliable and consistent performance for years to come. - Versatility:

Dover Motion’s linear translation stages are highly versatile, with a range of models and configurations available. Whether you require a single-axis stage or a multi-axis system, we have you covered. Our customization options allow you to tailor your stage to your specific application and requirements.