Dover Launches New Miniature Linear Stage with 5X the Force

Breakthrough Miniature Linear Stage delivers 5X more force and twice the force density compared to similar competitive products.

Boxborough, MA – Dover Motion, a leading technology solution provider for motion control systems, announces the launch of a new product, the MMX Miniature Linear Stage. This new stage is a high-performance version of Dover Motion’s Miniature Moving Magnet Stage (MMG) and offers a significantly higher force density compared to competitive offerings.

The unique capability of this stage can be attributed to the cutting-edge, patent-pending motor technology invented by the motion experts at Dover Motion.

In order improve the force density; the new MMX model features a number of unique features:

- Ironless motor delivers 100% cogging-free smooth linear motion.

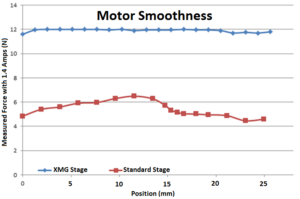

- Highly optimized motor to minimize force ripple and force variations. As shown in the below chart, force variation along the motor’s electrical cycle is minimal when compared to a typical linear motor stage because of its novel motor design. With a sinusoidal back EMF, the XMG stage ensures that the force ripple is also negligible.

These features are advantageous for applications such as stepping or scanning motion within a microscope, which requires a stable velocity or consistent force to move and settle as fast as possible. The high power direct drive motor generates less heat for the same motion profile as compared to less powerful motors, resulting in more accurate motion.

The high power direct drive motor in the MMX Miniature Linear Stage allows larger payloads and faster step and settle, for improved throughput. As a result, this product is extremely suitable for high throughput systems where a higher rate of acceleration is essential. In a 50 mm stroke stage, the MMG is capable of 14g acceleration. In the case of vertical applications, the MMX stages will self-support larger loads without any counterbalance due to the more powerful motor. The benefit is a simpler installation and lower costs for purchasing and adjusting extra components such as magnetic or air counterbalance hardware. This product is also useful for applications where excessive motor heat gain will negatively affect the working environment or positioning performance.

For more than five decades, Dover Motion has been delivering high-end motion control solutions for motion axes, structure, software interface development, optics, and vision integration. Utilizing a quality management system in accordance with ISO9001:2008 for the Design and Manufacture of Precision Positioning Products and Motion, the company is dedicated to ensuring the highest level of operational excellence. Implementing the Fortive Business System approach to lean manufacturing Dover Motion provides on time delivery of high quality best in class products.

Highlighting the uniqueness of the company’s new product offering, Dover Motion’s Senior Marketing Manager, John Garrity states, “The new ironless motor design used in the MMX has a unique design which significantly increases the force density of the motor. It also behaves differently from previous models, as there is no iron or steel backing to cause cogging of the motor. The Dover Motion engineering design team collaborated to optimize both the coil and magnet track to produce the best possible linear motor.”

To find out more about Dover Motion’s new MMX linear stage, please visit www.dovermotion.com/miniature-linear-stage