Translation Stages

If you’re in the market for translation stages, also called linear translation stages, you may be overwhelmed by the number of options available. Since not all stages are created equal, choosing a model that offers the right performance, throughput, and budget is important.

Our core strength is collaborating with our clients to understand their unique challenges and configure the right motion solution to fit their unique applications. Dover Motion’s product catalog includes many types of translation stages utilizing direct drive linear motors or stepper motors. Our stages are optimized for various uses, including precision motion, high speed, and compact size.

About Translation Stages

What is a translation stage?

A translation stage, also known as a linear translation stage or XY stage, is a mechanical device employed in a motion system to move an object precisely in a linear direction. It is widely used in research and industrial applications that require high-precision positioning and movement of small objects, such as microscopy and optical alignment.

There are two types of translation stages based on the control system used:

- Manual stages, controlled by manually turning a knob or a screw

- Motorized stages, controlled through a computer to achieve high accuracy and repeatability.

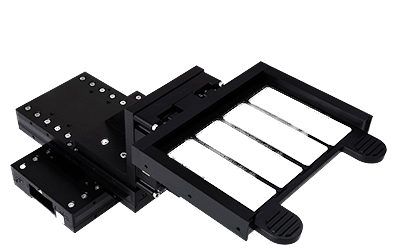

Translation stages are typically available as either a single axis or multi-axis, including an XY stages, or XYZ stages. Each axis of the stage must constrain the six degrees of freedom (X, Y, Z, roll, pitch, and yaw) of the payload to only one, producing translation along a straight line. This is accomplished with a set of linear bearing guideways attached to a base structural member that provides stiff support. Linear stages designed specifically for vertical motion can be viewed on our Z Stages page.

The linear bearing guideways can be implemented in a number of ways, including:

- Ball and crossed roller bearings

- Recirculating bearings

- Cam followers or vee wheels

- Air bearings

How does a translation stage work?

Once the payload has been constrained to a single degree of freedom, the system’s next mission is to actuate the payload and provide precise incremental linear motion along the guideway.

Linear actuator methods include:

- Friction screws with anti-backlash nuts

- Ball screws

- Belt and pulley

- Rack and pinion

- Piezo actuators

- Linear motors

Using a linear motor is generally considered to be optimal for high speed motion systems and is the most precise and repeatable linear motion actuation technology.

A stage with a linear motor, also called a linear translation stage, requires a linear feedback device as well as a servo drive and control to close a position feedback loop. With a high-resolution linear encoder, linear actuators can provide position control down to the nanometer level. A typical application for high precision linear actuators is to control the focus of a microscope objective in a digital imaging system.

What is the translation stage mechanism?

A translation stage mechanism is a type of motion control system that enables precise linear movement in a single direction. It typically consists of a linear motor, a ball screw, or a piezoelectric actuator, which allows for smooth and accurate movement in a controlled environment and can be customized based on the application requirements, such as speed, precision, and load capacity. The mechanism can be controlled manually or through a computer to achieve the desired position with high accuracy and repeatability.

What is a 3 axis translation stage?

The 3 axis translation stage is a type of motion control system used in engineering applications that requires precise positioning and movement of an object in three perpendicular directions. These stages typically consist of three linear actuators that enable movement in the X, Y, and Z axes.

The precision of 3-axis translation stages can range from a few microns to sub-nanometer levels, depending on the design and the quality of manufacturing. We can enhance the resolution and repeatability of the stage by adding feedback sensors such as encoders or interferometers. Engineers can integrate 3-axis translation stages with other motion control systems, such as rotary stages or robotic arms, to achieve complex motion profiles for advanced manufacturing, scientific research, or aerospace.

Our Key Advantage

- Precision:

One of the key advantages of Dover Motion’s linear translation stages is their precision. Our stages are designed to provide ultra-smooth and accurate movement, even in applications that require nanometer-level precision. This level of accuracy is essential for industries such as microscopy and semiconductor manufacturing, where even the slightest deviation can lead to major errors or defects. - Durability:

Another advantage of Dover Motion’s linear stages is their durability. Our stages are built to withstand even the most demanding applications up to 100,000km, with rugged construction and high-quality materials that ensure long-lasting performance. Whether you're using your stage in a laboratory setting or an industrial environment, it will provide reliable and consistent performance for years to come. - Versatility:

Dover Motion’s linear translation stages are highly versatile, with a range of models and configurations available. Whether you require a single-axis stage or a multi-axis system, we have you covered. Our customization options allow you to tailor your stage to your specific application and requirements.