Precision Motion Stages for Metrology Applications

Precision Positioning for High Accuracy Measurement Systems

Precise linear, rotary motion and air bearing stages play a critical role in today’s metrology and inspection systems—they ensure accurate, repeatable measurements across multiple metrology applications. We specialize in building compact, customizable motion systems that reduce design complexity, enhance accuracy, and simplify integration—empowering engineers to deliver faster and smarter metrology solutions.

Metrology Applications We Empower:

Our motion solutions are integral to a wide range of metrology applications, including:

- Optical / interferometry dimensional metrology

- Optical profilometer

- Surface metrology

- Contact / CMM

- Nano indenter

- Optical inspection (general / PCBA inspection)

Recommended Products:

SmartStage™ XY Monolithic Stage

The SmartStage XY Monolithic stage, is a linear motor stage in a low-profile XY form factor, with physically integrated controller, designed for precision positioning.

| wdt_ID | Travel | 50 - 75 mm |

|---|---|---|

| 1 | Accuracy | 12 μm |

| 2 | Repeatability | 0.8 μm |

| 3 | Payload (kg) | 10 kg |

XYA™ Linear Stage

The Dover XYA™ series XY linear stage incorporates the motor and controller into the body of the stage. Covers provide pinch point protection during motion.

| wdt_ID | Travel | 100 - 200 mm |

|---|---|---|

| 1 | Accuracy | 50 μm TIR |

| 2 | Repeatability | 5 μm |

| 3 | Payload | 10 kg |

SmartStage™ Shuttle Long Travel Stage

The SmartStage Shuttle is a long travel linear stage, which provides linear motor precision and throughput for XY stage applications.

| wdt_ID | Travel | 200 - 500 mm |

|---|---|---|

| 1 | Accuracy | 5 μm |

| 2 | Repeatability | 1.2 μm |

| 3 | Payload | 10 kg |

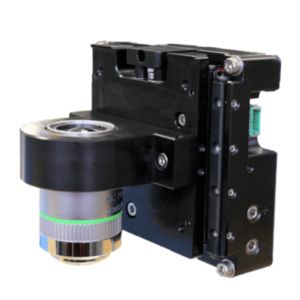

AG™

The Airglide™ air bearing stage design uses precision stiff air bearings for large payloads.

| wdt_ID | Travel | 150 - 400 mm |

|---|---|---|

| 1 | Accuracy | 4 μm TIR |

| 2 | Repeatability | < ± 0.4 μm |

| 3 | Payload | 40 kg |

FB™

FiberBeam™ linear air bearing positioners are designed for high accuracy in a low profile.

| wdt_ID | Travel | 20 - 100 mm |

|---|---|---|

| 1 | Accuracy | 2 μm TIR |

| 2 | Repeatability | < ± 0.1 μm |

| 3 | Payload | 15 kg |

Why Choose Dover Motion?

Unmatched precision: Our stages and systems are engineered for sub-micron and even nanometer-level accuracy and repeatability, crucial for the most demanding metrology applications.

Customizable Solutions: We excel in collaborating with OEMs to develop customizable XY, XYZ, rotary, and air bearing stages tailored to specific instrument needs.

Robust & Reliable: Built for continuous operation in challenging industrial environments, our stages ensure long-term stability and minimal downtime.

Advanced Control Capabilities: Leveraging our Motion Synergy™ API and sophisticated control algorithms, we enable precise motion profiles, high-speed triggering, and advanced synchronization for complex metrology sequences.

Deep Industry Experience: We have decades of experience shipping motion systems for semiconductor, display inspection, and hard drive applications.

Integrated Solutions: From individual components to complete multi-axis systems, we provide comprehensive motion solutions, simplifying integration and accelerating time to market.

Additional High Precision Motion Resources

Contact Us

Request a Demo Short

"*" indicates required fields