Custom Stages

Custom stages are highly specialized and precisely engineered motion control devices designed to meet your specific application requirements, such as extreme temperature ranges, high load capacity, compatibility with a specific control system, etc.

At Dover Motion, we are experts in designing and manufacturing custom stages for a wide range of industries and applications. From gene sequencers to digital pathology instruments, we have the expertise and experience to deliver high-quality custom stages that meet your unique needs.

Custom Stage Design Capabilities

SmartStage Open Frame (XY)

- Fast Linear Motors

- Built In controller

- High Resolution encoder feedback

XY + Tip Tilt Stages

- Long travel high speed load / unload stage

- Precision stepping axis

- Tip / Tilt to compensate for slide variation

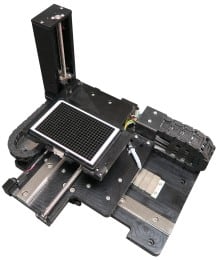

Well Plate XYZ Stage

- Optimized for price/performance

- Linear Motor high speed stepping axis

- Screw based indexing and Z lift axis

- Standard well plate carrier

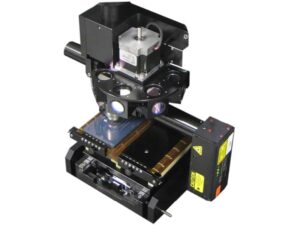

Gene Sequencing Imaging Sub-Assembly

- XY Stages moving a flow cell

- Z stage for objective focusing

- Integrated laser autofocus

Custom Stage Compact Designs

- Compact Design

- Built in controller

- High Resolution encoder feedback

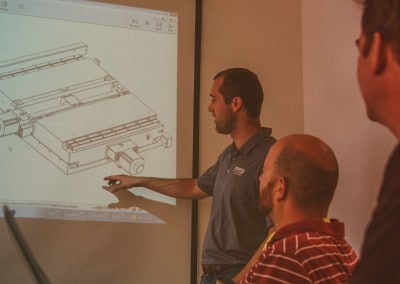

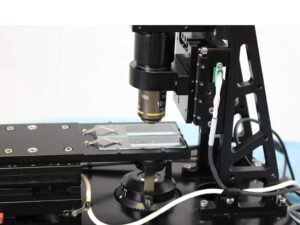

Microscope Demo

- DOF Objective Focusing Stage

- Linear Motor XY for slide positioning

- Customized Structure

Custom Stage Selection Checklist

Opting for a custom stage offers the potential to achieve higher levels of precision, accuracy, and repeatability, as well as better integration with the overall system. Let’s review the factors to consider while selecting a custom stage for your application by answering the questions below.

Please click on the plus icon below to expand the section.

What Custom Stage Attributes Can We Modify?

- Travel Distance

- Payload

- Size

- Controller Type

Benefits of Using Custom Stages

There are many benefits of using custom stages, including improved precision, efficiency, and reliability. Custom stages can help you reduce maintenance and replacement expenses over time, resulting in significant cost savings. So, if you're looking for a motion control partner that can provide you with superior custom stages, look no further than Dover Motion.

Review all benefits of using custom stages below:

- Improved Precision: Custom stages are designed to meet specific application requirements, which means that they can achieve higher levels of precision and accuracy compared to off-the-shelf stages. This improved precision can result in better performance and more reliable results.

- Increased Flexibility: Our stages can be tailored to meet your specific needs, resulting in improved flexibility, better performance and more efficient operations.

- Reduced Downtime: Custom stages can also be more reliable and less prone to failure compared to off-the-shelf stages, leading to reduced downtime and increased productivity.

- Improved Control: Our stages can be designed to work seamlessly with other components and subsystems in an instrument which means that they can provide improved control and performance. This improved control can result in better overall system performance and more reliable results.

- Cost Savings: Despite being a larger investment initially, custom stages provide significant cost savings in the long run due to their enhanced efficiency and reliability. Custom stages that are tailored to your specific application needs can lead to decreased maintenance and replacement costs over time.

At Dover Motion, we understand the importance of custom stages in achieving optimal application performance. That's why we work closely with our customers to design and manufacture stages that meet their unique requirements. From concept to production, we are committed to delivering high-quality stages that offer superior performance, reliability, and efficiency.

Contact us today to learn more about our custom stage design and manufacturing capabilities.