High Precision Linear Actuators

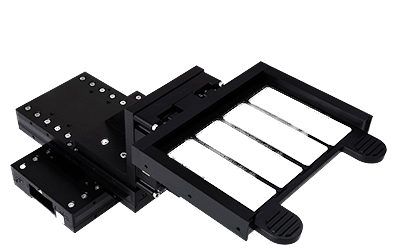

A precision linear actuator, also known as an XY stage and XY table delivers highly accurate automated positioning and is available in single-axis, XY, or XYZ configurations. Each axis of the actuator controls one degree of freedom (X, Y, Z, roll, pitch, or yaw), enabling precise linear motion. This is achieved using linear bearing guideways, which are mounted on a rigid base to ensure stability and support.

Dover Motion’s catalog includes many types of high precision linear actuators utilizing direct drive linear motors or stepper motors. Our actuators are optimized for various uses, including precision motion, high speed, or compact size.

High Precision Linear Actuators Overview

See How We are Disrupting Motion Control

Our innovative precision linear actuators have been winning industry awards

Linear Actuator Guide

Need to know a little bit more before you can make a decision? Below is additional information about high precision linear actuators and how they work. Contact us to speak with our staff, who can answer any of your technical questions.

What is a High Precision Linear Actuator?

High precision linear actuator, also commonly referred to as XY stage, XY Table , or Translation Stage, provides precise automated positioning and is typically available as either a single axis, an XY stage, or XYZ stage. Each axis of a linear actuator must constrain the six degrees of freedom (X, Y, Z, roll, pitch, and yaw) of the payload to only one, producing translation along a straight line. To accomplish this, the actuator is equipped with a set of linear bearing guideways, which are attached to a base structural member that provides stiff support.

The linear bearing guideways can be implemented in several ways, including:

- Ball and crossed roller bearings

- Recirculating bearings

- Cam followers or vee wheels

- Air bearings

Our linear actuators designed specifically for vertical motion can be viewed on our Z Stages page.

How do precision linear actuators work?

Once the payload has been constrained to a single degree of freedom, the system’s next mission is to actuate the payload and provide precise incremental linear motion along the guideway.

High precision linear actuator methods include:

- Friction screws with anti-backlash nuts

- Ball screws

- Belt and pulley

- Rack and pinion

- Piezo actuators

- Linear motors

Using a linear motor is generally considered to be optimal for high speed motion systems and is the most precise and repeatable linear motion actuation technology.

An actuator with a linear motor requires a linear feedback device as well as a servo drive and control to close a position feedback loop. With a high-resolution linear encoder, linear actuators can provide position control down to the nanometer level. A typical application for linear actuators is to control the focus of a microscope objective in a digital imaging system.

What are the most precise actuators?

Linear motor actuators and piezoelectric actuators are both known for delivering high precision, but linear motor actuators offer several technical advantages.

Linear motor actuators use direct-drive technology to enable frictionless, high-speed motion with exceptional accuracy and repeatability over longer travel distances. They maintain precision even under higher loads, making them suitable for demanding applications such as microscopy, cell imaging, and automated metrology. Their direct control of position through feedback systems ensures smoother motion compared to piezo actuators, which suffer from travel limitations and hysteresis effects.

While piezo actuators offer sub-nanometer precision, they come with significant drawbacks. They are limited in travel range, typically only reaching 10-200 microns, and are prone to issues like hysteresis (movement inconsistency), drift, and high costs. Additionally, their performance diminishes with heavier payloads, and their complexity increases in closed-loop systems, leading to reduced bandwidth and slower operation. In many applications, other technologies, such as linear motor actuators, provide superior travel, speed, and efficiency at a lower cost.