Linear Positioning Systems

A linear positioning system provides precise motion along a linear axis using various techniques, such as lead screws, ball screws, and linear motors. These systems are widely used in fields like life sciences and diagnostics, where they ensure accurate movement for applications such as microscopy, DNA sequencing, and cell analysis. High-precision technologies, including linear encoders and laser interferometers, further enhance system accuracy.

Linear Positioning System Capabilities

Tip/Tilt Slide Stage Mounted on an XY

- High speed / long travel lower axis stage for sample load and unload

- Smooth & stiff upper axis for high throughput field to field stepping

- Tip / Tilt stages compensate for slide variation & ensure focus

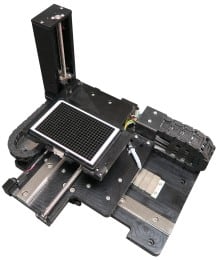

Well Plate XYZ Positioning System

- Hybrid stepper and linear motor combination optimized for price & performance

- Precision linear motor high speed Y axis

- Lead screw based lower X axis and Z lift indexing axes

- Integrated standard well plate carrier

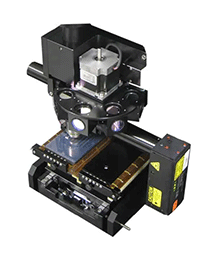

NGS Motion Sub-Assembly

- Stepper based filter changer

- Precision crossed roller bearing XY stages for flow cell positioning

- Linear motor Z stage for objective focusing

- Integrated laser autofocus for high throughput

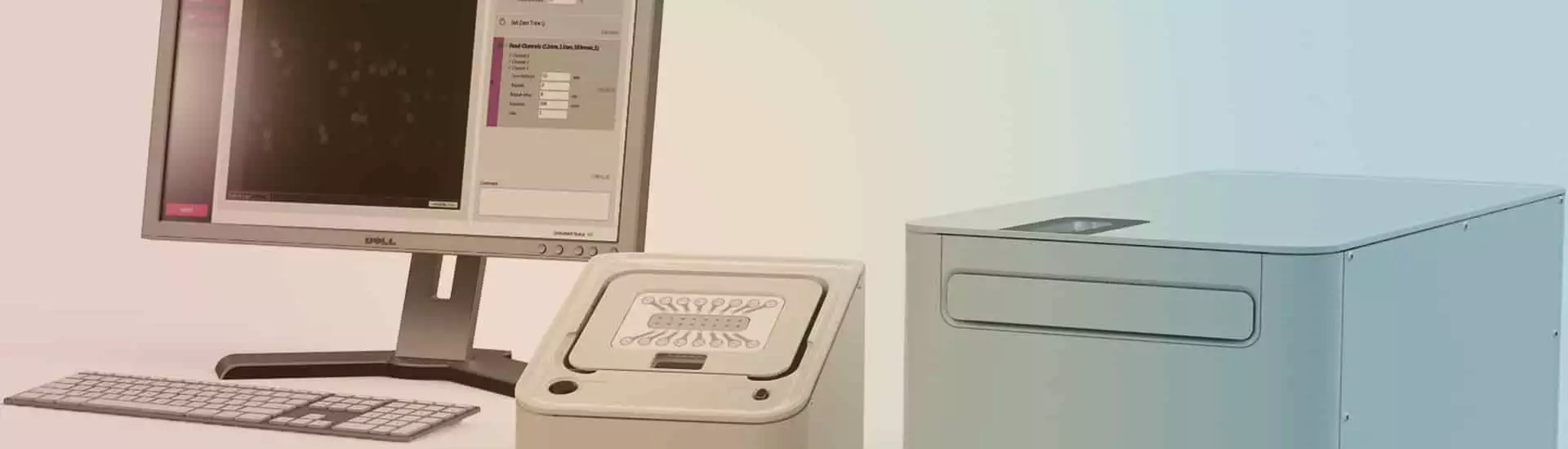

Point of Care Slide Imaging Subsystem

- Optimized miniature XYZ stage design with built-in controls

- Single slide XY motion

- 5nm resolution encoder feedback

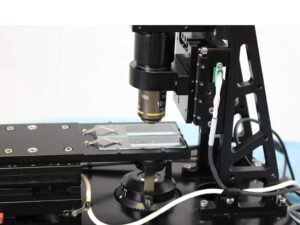

Microscope Linear Positioning System

- DOF objective focusing stage

- Linear motor XY stage for slide scanning

- Custom structure with built in vibration isolation

The Ideal Linear Positioning System for Your Application

With over 60 years of experience in life sciences, diagnostics, and factory automation, we understand your industry's challenges and offer the flexibility to meet your cost and schedule goals. Whether you need a standard motion product or a completely custom linear positioning system, we’ll work closely with your team to ensure your project meets even the toughest design and budget targets. Our collaborative approach ensures we provide motion solutions that align perfectly with your requirements.

Linear Positioning System Types

Linear positioning systems are categorized based on their technology and application requirements. The main types include:

- Lead screw based systems, ideal for low to moderate accuracy and cost-effective applications. Leadscrew based systems, often utilized in open-loop configurations, manage errors like backlash and thermal expansion, ensuring reliability.

- Linear motor with encoder systems offer higher resolution by eliminating mechanical errors.

- Laser interferometer systems are known for achieving the highest precision by minimizing Abbé and cosine errors through advanced feedback mechanisms.

Each system type addresses specific needs, such as minimizing backlash, managing thermal expansion, and improving geometric alignment, ensuring optimal performance across various industrial and scientific applications. Let's explore the different types of linear positioning systems individually to understand how they address these needs.

Functions of a Positioning System:

Linear positioning systems are used in a variety of applications that require accurate and repeatable motion. Some specific functions include:

- Precise positioning of objects: Linear positioning systems can be used to position objects with a high degree of accuracy. This is essential for many applications, such as microscopy and DNA sequencing.

- Movement of objects: Linear positioning systems can be used to move objects in a straight line. This is useful for applications such as robotics and automation.

- Control of motion: Linear positioning systems can be used to control the speed and acceleration of objects. This is important for applications that require precise control of motion, such as cell analysis and sorting.

Linear Positioning System FAQ

Linear Positioning System Resources

Cell Imaging Using Multi Axis Stages

Through concurrent and collaborative engineering, Dover Motion developed a compact custom XYZ stage motion solution to produce high-precision cell imaging in parallel with the instrument design.

Fluorescence Microscope XYZ Stage

Dover Motion defined the motion system requirements and tightly integrated the hardware in the overall instrument design, enabling the client to get the funding they needed to continue their project.

New XY Stage for 3D Metrology

To reduce the overall size, Dover Motion used compact stepper motors with integrated lead screws. Placing the motors within the stage structure enabled all wiring to be concealed and to exit at the bottom of the stage.

Use of a linear motor with an encoder eliminates concern over the lead screw cumulative and periodic error, as well as friction induced thermal expansion. In many systems, the lead screw can be dispensed with altogether and replaced with a non-contacting linear motor. With intrinsic accuracies on the order of 5 microns per meter,

Use of a linear motor with an encoder eliminates concern over the lead screw cumulative and periodic error, as well as friction induced thermal expansion. In many systems, the lead screw can be dispensed with altogether and replaced with a non-contacting linear motor. With intrinsic accuracies on the order of 5 microns per meter,