Long Travel Linear Stages: 200+ mm

Dover Motion designs and manufactures long travel linear stages, for high-precision motion control in demanding industrial, semiconductor, and life science applications. Featuring our powerful direct drive and linear motor technology, our stages deliver travel lengths from 200 millimeters up to 685 millimeters, with up to 175 kg max payloads and 5 μm accuracy.

In addition to our standard product configurations, Dover Motion offers custom long travel linear stage solutions designed to meet unique payload, speed, and precision requirements. Explore our range of long travel stages below to find the stage that fits your application.

Long Travel Linear Stage Products

The SmartStage Shuttle is a long travel linear stage, which provides linear motor precision and throughput for XY stage applications.

| wdt_ID | Travel | 200 - 500 mm |

|---|---|---|

| 1 | Accuracy | 5 μm |

| 2 | Repeatability | 1.2 μm |

| 3 | Payload | 10 kg |

The MMS™ – Miniature Long Travel Linear Stage ideal for imaging applications where a long travel load/unload axis is required.

| wdt_ID | Travel | 200 - 400 mm |

|---|---|---|

| 1 | Accuracy | < 15 μm |

| 2 | Repeatability | 2 μm |

| 3 | Payload | 12 kg |

The XYR™ series XY positioning stage uses a lead screw for motion. The monolithic integrated XY center makes the stage stiff and compact.

| wdt_ID | Travel | 50 - 300 mm |

|---|---|---|

| 1 | Accuracy | 15 μm |

| 2 | Repeatability | < ± 3 μm |

| 3 | Payload | 175 kg |

The XYRB™ series precision XY stage is similar to the XYR™, but incorporates a ball screw for more precise and repeatable positioning. The encoder option improves accuracy.

| wdt_ID | Travel | 50 - 300 mm |

|---|---|---|

| 1 | Accuracy | 8 μm TIR |

| 2 | Repeatability | < ± 1 μm |

| 3 | Payload | 175 kg |

The XYL™ series long travel linear stage has the largest table size, longer travels, and larger bearings for a stiffer platform that can handle larger payloads.

| wdt_ID | Travel | 300 - 685 mm |

|---|---|---|

| 1 | Accuracy | 35 μm TIR |

| 2 | Repeatability | < ± 3 μm |

| 3 | Payload | 175 kg |

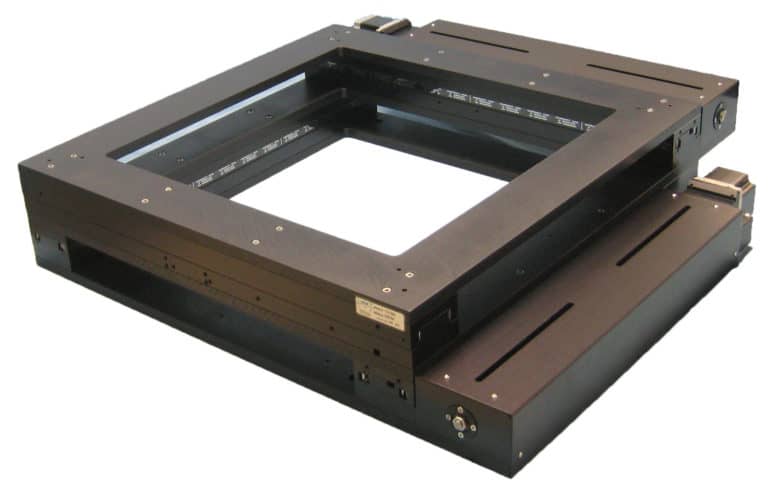

The OFL™ series motorized XY stage provides increased travel and load bearing capacity in an open frame XY configuration.

| wdt_ID | Travel | 200 - 635 mm |

|---|---|---|

| 1 | Accuracy | 80 μm TIR |

| 2 | Repeatability | < ± 3 μm |

| 3 | Payload | 80 kg |

The FM™ series is a ball screw linear stage with a stiffer table and larger crossed roller bearings.

| wdt_ID | Travel | 100 - 350 mm |

|---|---|---|

| 1 | Accuracy | 5 μm TIR |

| 2 | Repeatability | < ± 1.5 μm |

| 3 | Payload | 115 kg |

The Airglide™ air bearing stage design uses precision stiff air bearings for large payloads.

| wdt_ID | Travel | 150 - 400 mm |

|---|---|---|

| 1 | Accuracy | 4 μm TIR |

| 2 | Repeatability | < ± 0.4 μm |

| 3 | Payload | 40 kg |