XY Stages

An XY stage is a precision device used in linear positioning applications requiring high-precision movement such as automated microcopy. By allowing motion in two degrees of freedom, the XY stage is able to accurately position the sample and ensure complete sample coverage under a microscope for imaging or analysis.

We offer a variety of XY stages with different travel ranges and configurations to suit your specific application needs. Explore our full range of XY stage products below to find the perfect fit for your project.

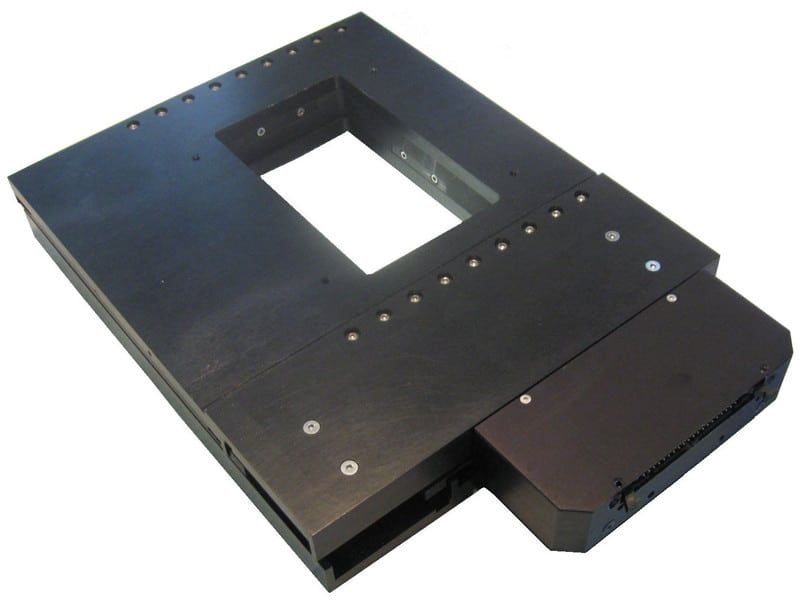

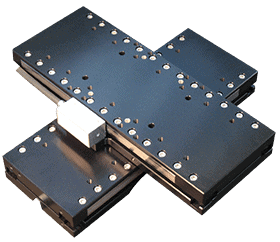

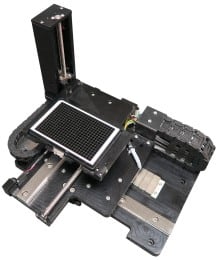

Compact High Performance XY Stages

Compact, high performance XY stages utilize stacked individual axes to create XY motion. Crossed roller bearing stages such as the SmartStage XY and MMX offer better stiffness and repeatability but have limited travel. Alternatively, the MMS series linear guide rail and carriage bearing assembly offers longer travels with slightly less repeatability.

The SmartStage™ XY linear positioning stage offers high precision and includes an embedded controller inside the stage.

| wdt_ID | Travel | 50 - 200 mm |

|---|---|---|

| 1 | Accuracy | ≤ 10 μm |

| 2 | Repeatability | 0.8 μm |

| 3 | Payload | 10 kg |

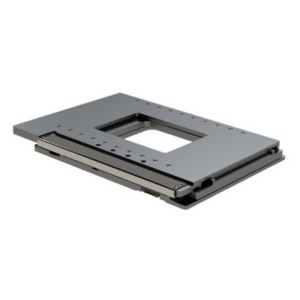

Open Frame XY Stages

Open frame XY stage products have an open aperture that allows for illuminating a sample from one side with the camera, optics, and objective on the other side of the sample. This arrangement is referred to as non-epifluorescence imaging. A typical microscope would have the illumination source below the sample and the camera/detector above the sample, while an inverted microscope has the opposite arrangement with the camera and objective below the stage. Having a clear aperture is helpful as it takes up less space than cantilevering the sample.

The SmartStage™ Open Frame XY is the first open aperture linear motor stage with an embedded controller physically integrated inside the stage.

| wdt_ID | Travel | 115 x 75 mm |

|---|---|---|

| 1 | Accuracy | ≤ 10 μm |

| 2 | Repeatability | 0.8 μm |

| 3 | Payload | 10 kg |

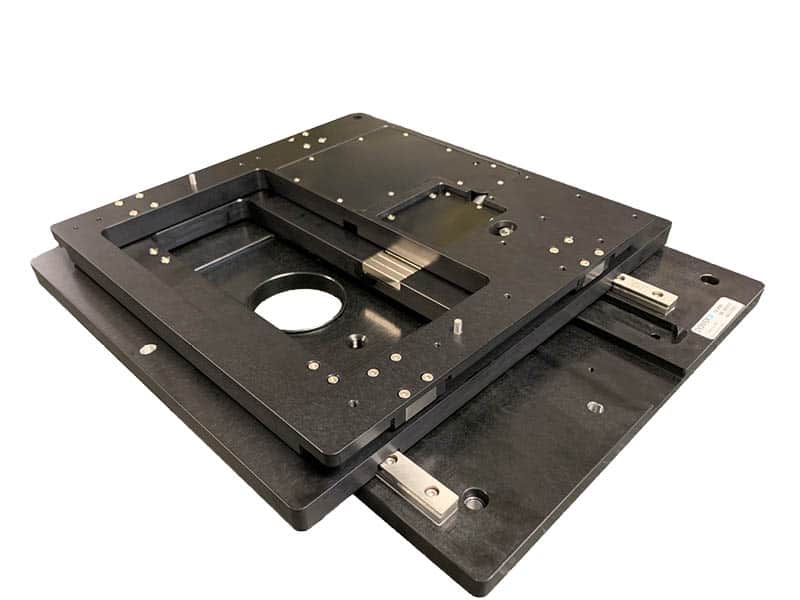

Monolithic High Load XY Stages

Monolithic style XY stages are used for larger loads and when there is a need to reduce height. The middle plate is both the table of the lower axis as well as the base of the upper axis. By using a monolithic integrated approach, a stiffer overall motion stage design is achieved which allows for a lower overall stack height, which helps minimize Abbe errors getting introduced into the accuracy of the motion.

The XY Monolithic positioning stage, is a linear motor stage in a low-profile XY form factor, with physically integrated controller, designed for precision positioning.

| wdt_ID | Travel | 50 - 75 mm |

|---|---|---|

| 1 | Accuracy | 12 μm |

| 2 | Repeatability | 0.8 μm |

| 3 | Payload (kg) | 10 kg |

The Dover XYA™ series XY linear stage incorporates the motor and controller into the body of the stage. Covers provide pinch point protection during motion.

| wdt_ID | Travel | 100 - 200 mm |

|---|---|---|

| 1 | Accuracy | 50 μm TIR |

| 2 | Repeatability | 5 μm |

| 3 | Payload | 10 kg |

Custom Design Capabilities

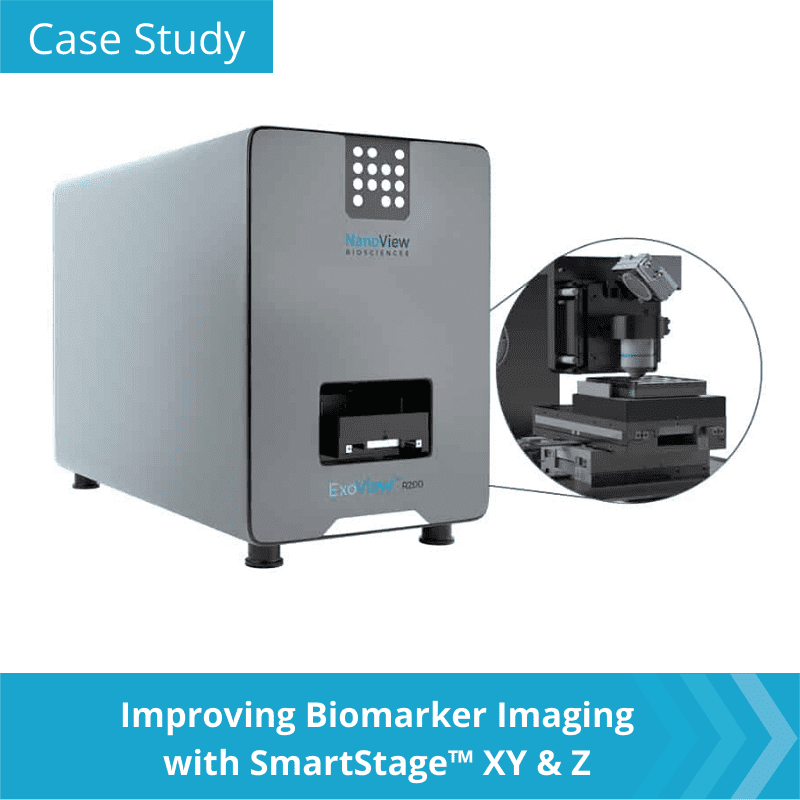

Dover Motion has more than 25 years of experience working with OEMs to optimize motion for objective focusing, and moving samples on slides, well plates, or flow cells.

Our engineers have developed unique motion control architectures for precision motion specifically tailored to the needs of OEMs developing microscope-based systems and instruments relying on optical imaging as the analytical detection technique. Dover Motion’s novel, patented, SmartStage embedded controls provides key packaging advantages, reduced cabling and cable management requirements, and incredible system value for our clients.

Whether your project requires a customization to a standard product or a completely custom design, we’ll collaborate with your team to ensure to hit even the most challenging design, cost, and schedule targets.

- Long travel high speed load / unload stage

- Precision stepping axis

- Tip / Tilt to compensate for slide variation

- Optimized for price/performance

- Linear Motor high speed stepping axis

- Screw based indexing and Z lift axes

- Standard well plate carrier

Additional Resources

XY Stages FAQ

While a number of positioning actuator applications can be addressed with single-axis stages, the majority of customer payloads require motion in two axes, for which we use an XY stage, also called an XY table. In its simplest configuration, an XY stage can be assembled by simply bolting two single-axis stages together. In that case, care must be taken to ensure that the axes are truly orthogonal.

The preferred implementation is to make a true XY stage in which the orthogonality is precision-machined into its component parts. In this type of XY translation stage design, the top of the lower axis serves as the base for the upper axis, in a simple and compact three-piece design. This approach typically reduces the overall height of the XY stage resulting in less Abbe error. In addition, most of our actuators can be mounted in an XYZ configuration for vertical applications.

XY linear stages can be designed with a wide range of guideways including:

- Ball and pressure plate provide lower cost, but less stiffness

- Crossed roller guideways offer high stiffness and precision straightness across travel

- Recirculating profile rails are best for longer travels

- Air bearings provide the highest precision flatness and straightness

Dover Motion offers various actuation options including:

- Rotary stepper motor or rotary servo motor driving a lead screw and friction nut for low cost applications

- Rotary stepper motor or rotary servo motor driving a ball screws for better repeatability

- Rotary motor driven belts and pulleys where speed and cost is more important than precision

- Linear motors for the best reliability (non-contact with no wearing elements) and for high precision repeatability

XY linear stages with air bearings and linear motors provide some of the highest levels of performance available. The only assembly more precise is called a planar gantry design.

In a planar gantry system, the front to back axis consists of two individual axes, one on the left and one on the right, just as in the vertical lines of the letter “H.” A third axis runs left to right, as in the horizontal line of the letter “H,” and is driven at each end by the front to back axes. The payload carrier runs left to right along the third axis, but rests on a planar air bearing floating a few microns above a large area planar substrate (typically extremely flat granite). In a planar air bearing gantry stage, Z axis errors, as well as pitch and roll, are completely determined by the flatness of the granite substrate. Yaw can be controlled by fine flexural movements of the two ends of the third axis.

In many applications, an additional Z axis is required. This can either be added atop the XY stage, forming an XYZ stage, or the Z stage can be mounted separately, and control a payload relative to a separate customer part on the XY stage.

We have experience working with a variety of XY stage configurations and pride ourselves on being able to work within our clients’ parameters to help them reach their goals.

Contact us today to learn how Dover Motion can configure the right motion solution for your application.